World Coordinate System Of Robots Explained The Robotics Channel

World Coordinate System Learnchannel Tv In this video you will learn about the world coordinate system of an industrial robot, what it is and how you can use it to move your robot. On the robotics channel, you get free tutorials on how to program and use industrial robots. in this video, you can learn everything you need to know about the world coordinate system of robots, when to use it and how it works.

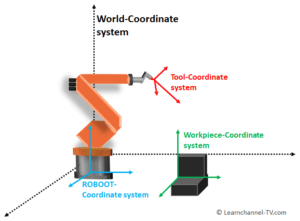

World Coordinate System Learnchannel Tv Because we want the robot to be able to use multiple tools and work on a variety of surfaces with different orientations, here are 3 coordinate systems that you need to understand in order to work the robots:. This section gives a introduction to coordinate systems that are often used in offline programming. in robotstudio, you can use all coordinate systems described below, as well as user defined coordinate systems, for relating objects and elements with each other. Robotic systems are generally defined as cartesian coordinate systems: the roboot koordinatensystem is a cartesian coordinate system, which has its origin at the footprint of a robot. it describes the position of the robot regarding the world coordintes. At the highest level there are two types of coordinate frames; global and local. in the global frame the robots position is specified based on a pre established method that can uniquely identify the robots position on earth (or any other planetary body location).

Robot Coordinate Systems Learnchannel Tv Robotic systems are generally defined as cartesian coordinate systems: the roboot koordinatensystem is a cartesian coordinate system, which has its origin at the footprint of a robot. it describes the position of the robot regarding the world coordintes. At the highest level there are two types of coordinate frames; global and local. in the global frame the robots position is specified based on a pre established method that can uniquely identify the robots position on earth (or any other planetary body location). Because we want the robot to be able to use multiple tools and work on a variety of surfaces with different orientations, here are 3 coordinate systems that you need to understand in order to work the robots:. In order to understand how these robots operate, it is crucial to grasp the concept of the world coordinate system and its significance in robot movement. in this article, we will explore the world coordinate system of industrial robots and delve into its practical use in various applications. Robotcoordinate system the industrial robot coordinate system widely follows the cartesian coordinate system. most industrial robot comprises of 6 degrees of freedom i.e. 6 axis arm robot. the coordinate system for industrial robot are robroot, world, tool, flange, base coordinate system. More complicated systems, such as mobile manipulators or multi legged robots, make life much easier by defining multiple coordinate systems, e.g. one for each leg and one that describes the position of the robot in the world frame.

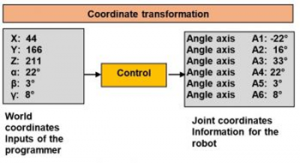

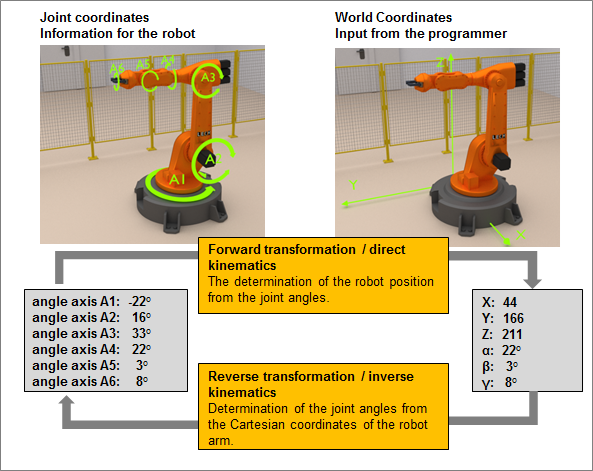

Coordinate Transformation Learnchannel Tv Because we want the robot to be able to use multiple tools and work on a variety of surfaces with different orientations, here are 3 coordinate systems that you need to understand in order to work the robots:. In order to understand how these robots operate, it is crucial to grasp the concept of the world coordinate system and its significance in robot movement. in this article, we will explore the world coordinate system of industrial robots and delve into its practical use in various applications. Robotcoordinate system the industrial robot coordinate system widely follows the cartesian coordinate system. most industrial robot comprises of 6 degrees of freedom i.e. 6 axis arm robot. the coordinate system for industrial robot are robroot, world, tool, flange, base coordinate system. More complicated systems, such as mobile manipulators or multi legged robots, make life much easier by defining multiple coordinate systems, e.g. one for each leg and one that describes the position of the robot in the world frame.

The Robot S Coordinate System Download Scientific Diagram Robotcoordinate system the industrial robot coordinate system widely follows the cartesian coordinate system. most industrial robot comprises of 6 degrees of freedom i.e. 6 axis arm robot. the coordinate system for industrial robot are robroot, world, tool, flange, base coordinate system. More complicated systems, such as mobile manipulators or multi legged robots, make life much easier by defining multiple coordinate systems, e.g. one for each leg and one that describes the position of the robot in the world frame.

15 World Coordinate System Download Scientific Diagram

Comments are closed.