What Are Pcb Functional Testing Services Electronicshacks

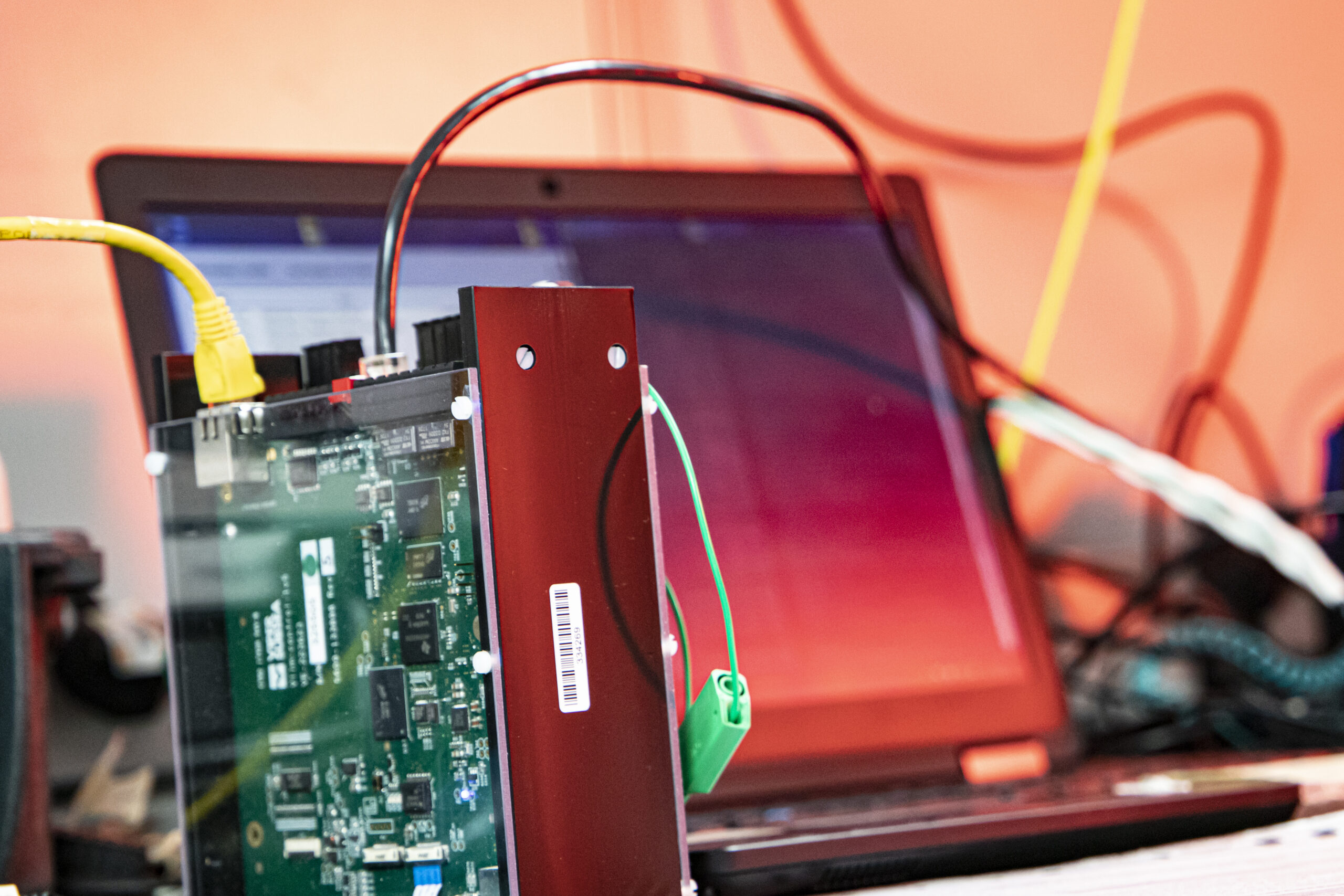

Functional Testing Active Pcb In this article, we will explore the importance of pcb functional testing services, the types of tests that are commonly performed, and the benefits of working with a reliable and experienced pcb functional testing service provider. Pcb functional testing is one such critical procedure performed on fully assembled boards to validate their functionality. this guide takes an in depth look at pcb functional testing – its meaning, methods, tools, importance and role in the manufacturing workflow.

Pcb Functional Testing Services Fct For Quality Assurance Pcb functional testing involves checking a printed circuit board by simulating its intended usage conditions. it is one of the final steps in the production process, ensuring assembled pcbs are ready for use. With functional testing, it’s possible to test up to 100% of the products before an ecm ships them to an original equipment manufacturer (oem, aka you). here are some popular pcb functional tests and how they do their job. What is pcb functional testing, and how is functional testing done? learn more about the value of pcb functional testing, why some organizations skip it — and come to regret that call — and why it’s worth the investment. Functional testing is a crucial step in the pcb manufacturing process, designed to verify that a pcb performs its intended functions correctly. this article provides a comprehensive overview of pcb functional testing, covering its importance, methodologies, challenges, and future trends. 1. the importance of pcb functional testing.

Functional Pcb Testing High Quality Pcb Testing Services Rush Pcb What is pcb functional testing, and how is functional testing done? learn more about the value of pcb functional testing, why some organizations skip it — and come to regret that call — and why it’s worth the investment. Functional testing is a crucial step in the pcb manufacturing process, designed to verify that a pcb performs its intended functions correctly. this article provides a comprehensive overview of pcb functional testing, covering its importance, methodologies, challenges, and future trends. 1. the importance of pcb functional testing. At active pcb solutions, we know the importance of quality and reliability in electronic assemblies, and our functional testing services are tailored to verify that each pcb meets your required operational specifications. functional testing is conducted after the assembly of the pcb. As a provider of pcb assembly services, ensuring the electrical functionality of printed circuit boards (pcbs) is a critical part of our quality control process. electrical functionality testing is essential to identify any defects or issues that could affect the performance of the final product. It will start by outlining the various stages of pcb testing, from design verification to functional testing. the article will then delve into the different testing techniques, such as visual inspection, automated optical inspection (aoi), x ray inspection, and in circuit testing (ict). Today, let's dive into the core of pcb manufacturing and reveal functional testing. what is pcb functional testing? pcb functional testing is a quality control means to verify all.

Significance Of Pcb Functional Testing And Its Methods At active pcb solutions, we know the importance of quality and reliability in electronic assemblies, and our functional testing services are tailored to verify that each pcb meets your required operational specifications. functional testing is conducted after the assembly of the pcb. As a provider of pcb assembly services, ensuring the electrical functionality of printed circuit boards (pcbs) is a critical part of our quality control process. electrical functionality testing is essential to identify any defects or issues that could affect the performance of the final product. It will start by outlining the various stages of pcb testing, from design verification to functional testing. the article will then delve into the different testing techniques, such as visual inspection, automated optical inspection (aoi), x ray inspection, and in circuit testing (ict). Today, let's dive into the core of pcb manufacturing and reveal functional testing. what is pcb functional testing? pcb functional testing is a quality control means to verify all.

Significance Of Pcb Functional Testing And Its Methods It will start by outlining the various stages of pcb testing, from design verification to functional testing. the article will then delve into the different testing techniques, such as visual inspection, automated optical inspection (aoi), x ray inspection, and in circuit testing (ict). Today, let's dive into the core of pcb manufacturing and reveal functional testing. what is pcb functional testing? pcb functional testing is a quality control means to verify all.

What Are Pcb Functional Testing Services Electronicshacks

Comments are closed.