Types Of Welding Processes Robots Can Perform Automation In

Types Of Welding Processes Robots Can Perform Automation In As a result, robots automatically can perform complex welding processes without any direct human intervention. most commonly, robotic welding is performed to weld metal components together. robotic welding basics. the process joins two metals together using a robotic arm and an electric arc. Robotic welding is the process of using an automation system to perform welding tasks. learn more about welding robots and how you can automate your first welding project today.

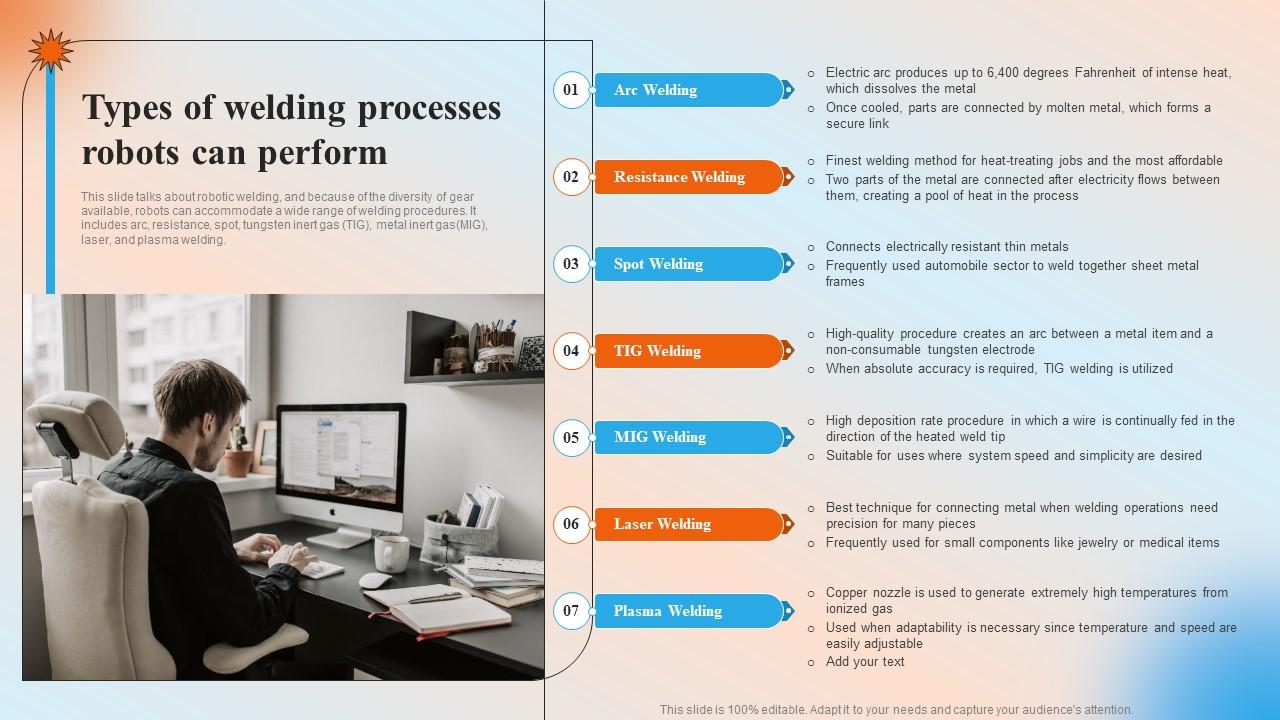

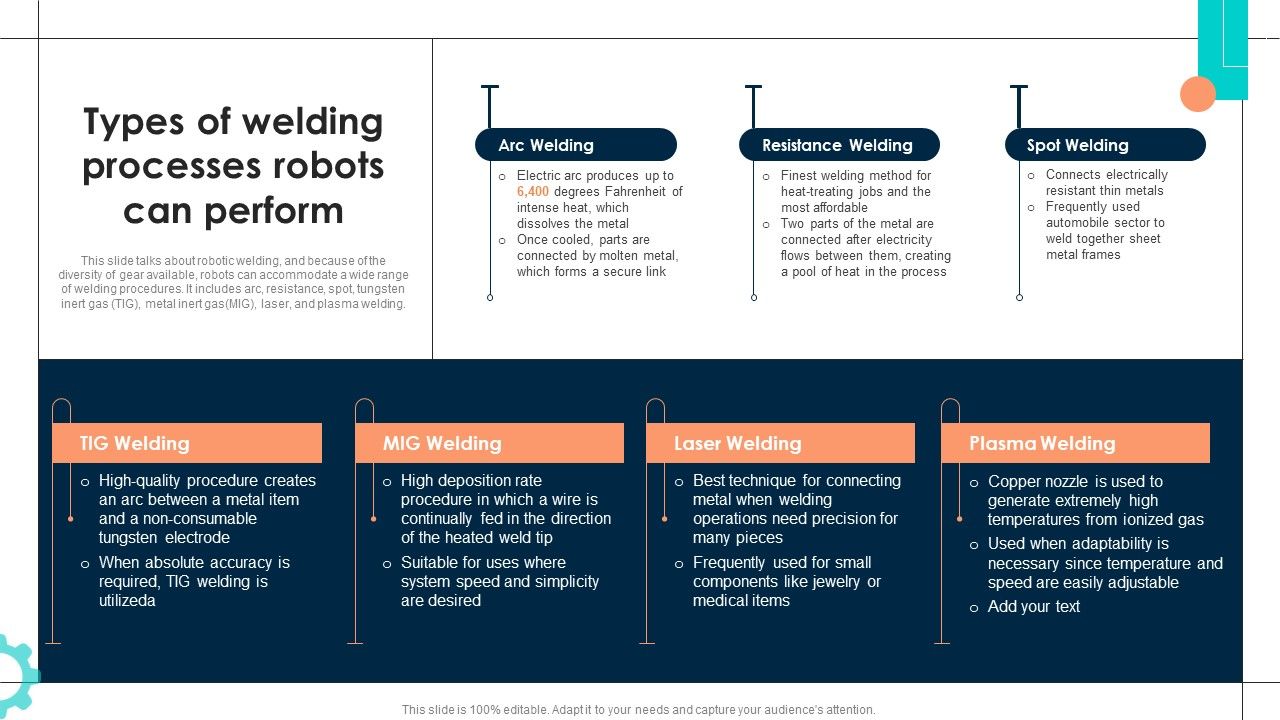

Types Of Welding Processes Robots Can Perform Pictures Pdf In this blog, we'll explain and simplify the main types of welding automation to help you start to understand which would be the best choice for your manufacturing process. There are two primary types of robotic welding: arc welding: also known as mig or tig welding, it uses an electric arc to create heat and melt the metal. spot welding: this method uses two electrodes to apply pressure and heat to the areas being welded. Robotic welding is commonly used in industries such as automotive and aerospace, where precision and consistency are paramount. the robots can be programmed to perform a wide range of welding techniques, including mig, tig, and spot welding, making them extremely versatile. Robotic welding can be classified into several types based on the welding technique used. each process has unique advantages and applications, catering to specific industry needs.

Intelligent Manufacturing Types Of Welding Processes Robots Can Perform Robotic welding is commonly used in industries such as automotive and aerospace, where precision and consistency are paramount. the robots can be programmed to perform a wide range of welding techniques, including mig, tig, and spot welding, making them extremely versatile. Robotic welding can be classified into several types based on the welding technique used. each process has unique advantages and applications, catering to specific industry needs. Typical examples of programmable welding automation include robotic mig or tig welding in metal fabrication. manufacturers often use it in production lines where components vary slightly in shape or size. Learn how robots can be integrated into welding processes, and what are the key aspects of robotic welding, such as types, applications, advantages, disadvantages, and future trends. As a leading supplier of industrial robots, we are well versed in the diverse types of welding that these robotic marvels can perform, each tailored to specific materials, joint configurations, and production requirements. 1. gas metal arc welding (gmaw). Robotic welding integrates various welding methods into automated systems, including arc, mig, tig, laser, and more. each type offers unique benefits for precision, efficiency, and application in robotic manufacturing environments. arc welding uses an electrical arc to melt workpieces and filler material to form a strong bond.

Comments are closed.