Taper Turning Methods In Lathe Machine Basic Types Of A 56 Off

Best 5 Taper Turning Methods In Lathe Machine Blogmech Lathe Cutting the metal on a lathe machine in such a way that, its surface makes an angle with the axis of the metal is called taper turning. the following are the various methods to which taper can represent. What types of materials are commonly used for workpieces when performing taper turning on a metal lathe? when we use a metal lathe for taper turning, we often work with materials like steel, aluminum, and brass.

Taper Turning Methods In Lathe Machine Basic Types Of A 52 Off This comprehensive guide provides an in depth explanation of taper turning on lathe machines, including different methods, tools, and techniques to achieve precise and accurate tapers. Read this article to explore what taper turning is, how it works, its importance, and everything you need to know to effectively implement taper turning in your machining operations. It describes different taper turning techniques used in lathe machines such as compound rest method, offset tailstock method, and taper attachment method. the document provides details on how each method works and when they should be used for turning tapers of various shapes and sizes. Taper turning is the process of producing a taper on the workpiece. tapers can come in many forms and can be cut with multiple different methods. short tapers can be cut using the compound rest. long, shallow tapers will need to be made with the tailstock offset method or the use of a taper attachment.

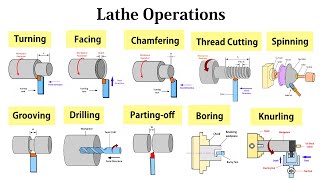

Taper Turning Methods In Lathe Machine Basic Types Of A 52 Off It describes different taper turning techniques used in lathe machines such as compound rest method, offset tailstock method, and taper attachment method. the document provides details on how each method works and when they should be used for turning tapers of various shapes and sizes. Taper turning is the process of producing a taper on the workpiece. tapers can come in many forms and can be cut with multiple different methods. short tapers can be cut using the compound rest. long, shallow tapers will need to be made with the tailstock offset method or the use of a taper attachment. The method used for turning a taper depends on the degree, length, location of the taper (internal or external), and the number of pieces to be done. the three basic methods of turning a taper require the operator to use either a compound rest, offset the tailstock, or use the taper attachment. There are three main methods for turning tapers on a lathe: using a taper attachment, compound rest, or offsetting the tailstock. the taper attachment moves the cutting tool at an angle relative to the workpiece to automatically produce a tapered shape. In this article, we list some basic operations of a lathe . Taper turning is a machining operation, which means that the diameter of cylindrical workpieces gradually decreases from one part to another. the taper can be external or internal. if the workpiece is taped outward, it has an outer taper. if it is taped inward, it has an internal taper.

30 Methods Of Taper Turning Pdf Mechanical Engineering Machines The method used for turning a taper depends on the degree, length, location of the taper (internal or external), and the number of pieces to be done. the three basic methods of turning a taper require the operator to use either a compound rest, offset the tailstock, or use the taper attachment. There are three main methods for turning tapers on a lathe: using a taper attachment, compound rest, or offsetting the tailstock. the taper attachment moves the cutting tool at an angle relative to the workpiece to automatically produce a tapered shape. In this article, we list some basic operations of a lathe . Taper turning is a machining operation, which means that the diameter of cylindrical workpieces gradually decreases from one part to another. the taper can be external or internal. if the workpiece is taped outward, it has an outer taper. if it is taped inward, it has an internal taper.

Comments are closed.