Solved In The V Belt Pulley Mechanism In The Figure The Chegg

Solved In The V Belt Pulley Mechanism In The Figure The Chegg In the v belt pulley mechanism in the figure, the length of the belt is 3092 mm. the speed of the belt is 15 m s. what is the interaxial distance? find the number of revolutions of the small pulley. find the power that can be transmitted for the service factor 1,2. here’s the best way to solve it. Problem 2: a countershaft carrying two v belt pulleys is shown in the figure. pulley b receives power from a motor through a belt with the belt tensions shown. the power is transmitted through the shaft and delivered to the belt on pulley a. for each pulley, the belt tensions are parallel.

Solved In The Belt Pulley Mechanism Shown In The Figure The Chegg Step 1: determine the load on each bearing to determine the load on each bearing, we need to consider the belt tensions and the forces acting on the pulleys. for pulley a: the tension on the tight side of the belt is 45 n. To solve this problem, we must first draw the **free body diagrams ** (fbd) for both pulley c and pulley d, taking into account all the forces acting on the pulleys. This formula is also important for ropes passing around drums and pulleys and governs the power that can be transmitted by a pulley drive before the belt slips. Friction in v belts a v belt is any belt that fits into a groove on a pulley or surface. for the v belt to be effective, the belt or cable will need to be in contact with the sides of the groove, but not the base of the groove as shown in the diagram below.

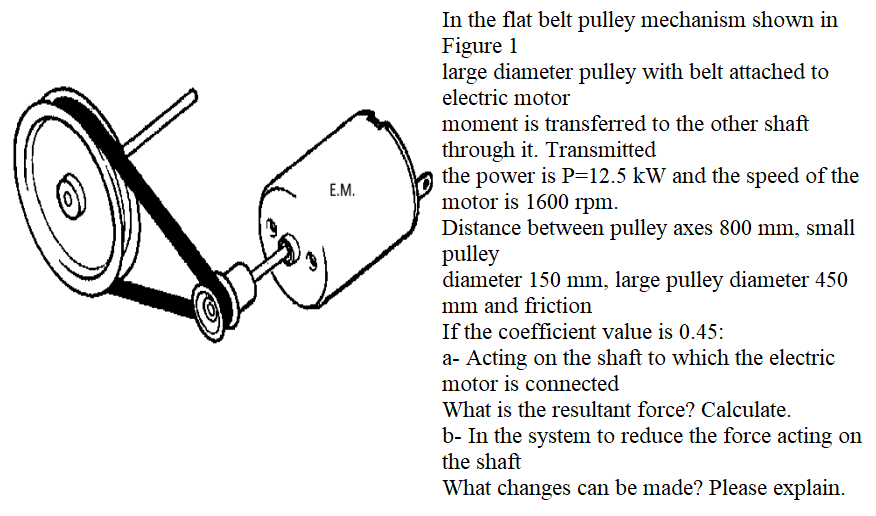

Solved In The Flat Belt Pulley Mechanism Shown In Figure 1 Chegg This formula is also important for ropes passing around drums and pulleys and governs the power that can be transmitted by a pulley drive before the belt slips. Friction in v belts a v belt is any belt that fits into a groove on a pulley or surface. for the v belt to be effective, the belt or cable will need to be in contact with the sides of the groove, but not the base of the groove as shown in the diagram below. Solved problems – belt drive system design problem 1 calculate the maximum power that may be transmitted by a flat belt driving a pulley 360 mm diameter which rotates at 180 rev min. Question: the v belt system drives the grinding and sawing machine as shown in figure q2. moderate to heavy shock loads are generated throughout the operation. a belt pulley system with a diameter of 200mm drives a cutting blade with a diameter of 550mm. two bearings are located at points a and b to support the shaft loads. Each example provides the relevant data, calculations, and solution for determining values like belt tension, power transmission, belt width, and initial tension. pulley diameters, rotational speeds, center distances, coefficients of friction, and transmitted power are given. Problem 2: a countershaft carrying two v belt pulleys is shown in the figure. pulley b receives power from a motor through a belt with the belt tensions shown. the power is transmitted through the shaft and delivered to the belt on pulley a. for each pulley, the belt tensions are parallel.

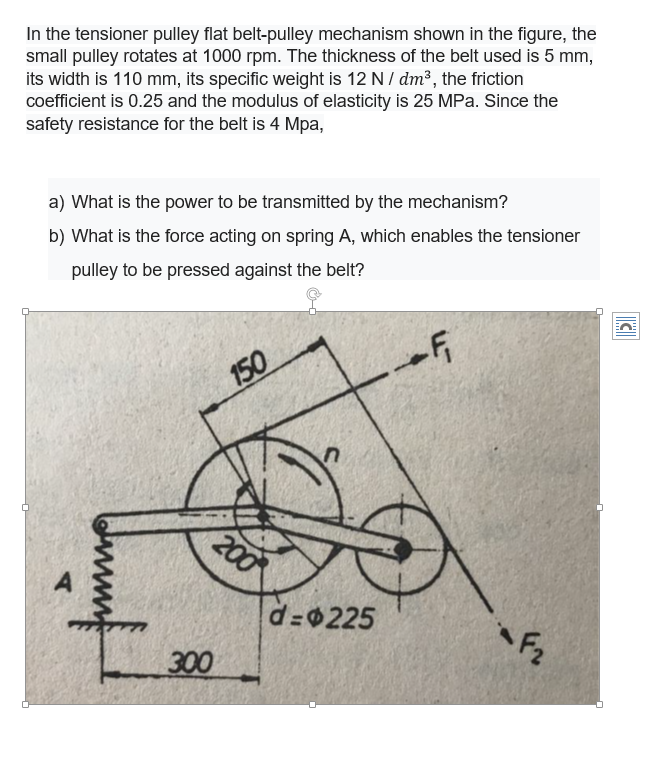

Solved In The Tensioner Pulley Flat Belt Pulley Mechanism Chegg Solved problems – belt drive system design problem 1 calculate the maximum power that may be transmitted by a flat belt driving a pulley 360 mm diameter which rotates at 180 rev min. Question: the v belt system drives the grinding and sawing machine as shown in figure q2. moderate to heavy shock loads are generated throughout the operation. a belt pulley system with a diameter of 200mm drives a cutting blade with a diameter of 550mm. two bearings are located at points a and b to support the shaft loads. Each example provides the relevant data, calculations, and solution for determining values like belt tension, power transmission, belt width, and initial tension. pulley diameters, rotational speeds, center distances, coefficients of friction, and transmitted power are given. Problem 2: a countershaft carrying two v belt pulleys is shown in the figure. pulley b receives power from a motor through a belt with the belt tensions shown. the power is transmitted through the shaft and delivered to the belt on pulley a. for each pulley, the belt tensions are parallel.

Comments are closed.