Small Cocoa Bean Processing Line Cocoa Bean Winnower And Cracker Coffee

Small Cocoa Bean Processing Line Cocoa Bean Winnower And Cracker Coffee Working principle: cocoa beans are fed, uniformly fed in the hopper, and peeled by rollers, then the ventilator sucks the peeled skins to the outside of the machine by wind for storage, and the peeled cocoa kernels pass through the material when the material is discharged from the mouth, by adjusting the size of the wind force and the size of. Cleanly separate cocoa nibs from husks with vulcano’s integrated cracker and winnower systems. explore our models — from 20 to 200 kg h — for any production scale.

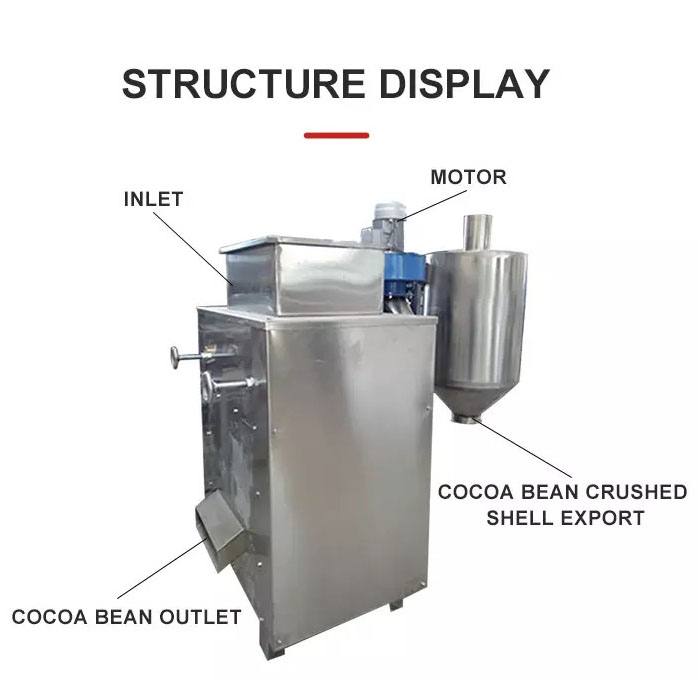

Small Cocoa Bean Processing Line Cocoa Bean Winnower And Cracker Coffee Following the cocoa roasting process, the roasted beans are introduced into the upper hopper of our machine. here, they undergo a delicate cracking procedure before being transported through a high performing vacuum system. This cocoa bean cracker and winnower machine can complete the purpose of cocoa crushing and winnowing at one time, and get ideal cocoa nibs, so this machine is an ideal equipment for processing cocoa beans. This machine is composed of peeling rollers, fans and specific gravity sorting parts. it has a simple and compact structure, easy operation, stable performance, safety and reliability. working principle: the cocoa beans are fed uniformly into the hopper, and are peeled by the peeling roller. then the ventilator. 2 x excellent condition cocoa bean processing lines including cleaning, winnowers, roasters and beater mills. most equipment manufactured by barth and bauermeister.

Small Cocoa Bean Processing Line Cocoa Bean Winnower And Cracker Coffee This machine is composed of peeling rollers, fans and specific gravity sorting parts. it has a simple and compact structure, easy operation, stable performance, safety and reliability. working principle: the cocoa beans are fed uniformly into the hopper, and are peeled by the peeling roller. then the ventilator. 2 x excellent condition cocoa bean processing lines including cleaning, winnowers, roasters and beater mills. most equipment manufactured by barth and bauermeister. Winnower with a capacity of up to 100 kg h, including pre hopper, dosing unit, bean breaker and suction system with cyclone and ventilator. housing, product hopper, cyclone and sieves in stainless steel. In conjunction with the spectra pro cracker, it can be an invaluable addition to your bean to bar enterprise. multiple control points in the feeder, suction, and flow system allow you to control the degree of separation of the husk from the nibs easily and finely. This compact, state of the art winnower can separate out up to 20 lbs (10kgs) of cracked cocoa beans per hour. using advanced airflow techniques, cocoat basic winnower efficiently separates cocoa nibs (cacao nibs) and husk, minimizing waste and cross contamination. Enhance your cacao processing workflow with our comprehensive dcv series of cocoa cracker, winnower & sorter machines. designed for efficiency and consistent results, each model ensures optimal cracking, winnowing, and sorting—delivering high quality nibs in a single pass.

Small Cocoa Bean Processing Line Cocoa Bean Winnower And Cracker Coffee Winnower with a capacity of up to 100 kg h, including pre hopper, dosing unit, bean breaker and suction system with cyclone and ventilator. housing, product hopper, cyclone and sieves in stainless steel. In conjunction with the spectra pro cracker, it can be an invaluable addition to your bean to bar enterprise. multiple control points in the feeder, suction, and flow system allow you to control the degree of separation of the husk from the nibs easily and finely. This compact, state of the art winnower can separate out up to 20 lbs (10kgs) of cracked cocoa beans per hour. using advanced airflow techniques, cocoat basic winnower efficiently separates cocoa nibs (cacao nibs) and husk, minimizing waste and cross contamination. Enhance your cacao processing workflow with our comprehensive dcv series of cocoa cracker, winnower & sorter machines. designed for efficiency and consistent results, each model ensures optimal cracking, winnowing, and sorting—delivering high quality nibs in a single pass.

Comments are closed.