Sensor Basics Whats The Difference Between A Flush Vs Non Flush Vs Factor1 Inductive Sensor

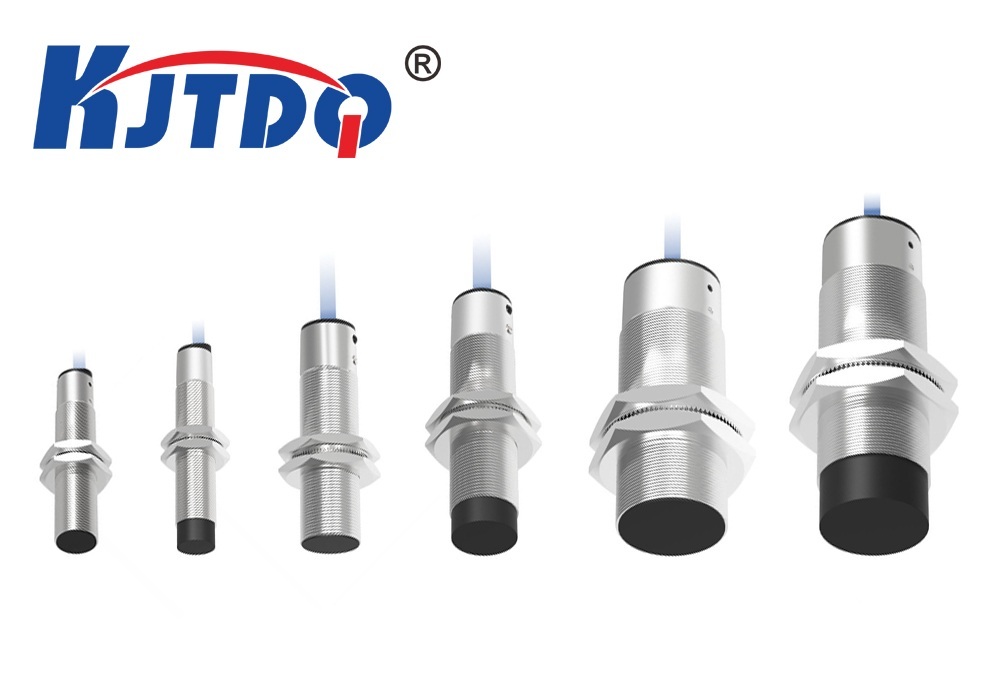

China Flush Non Flush Sensor Manufacturers Flush Non Flush Sensor Virtually every inductive proximity sensor vendor offers these three modes to allow for adaption to your specific application and target. There are several mounting options available for this type of sensor, including flush mount, non flush mount, and semi flush mount. we will dive into each type in more detail below.

China Flush Non Flush Sensor Manufacturers Flush Non Flush Sensor As the name indicates, flush mountable sensors can be fully integrated into the surrounding metal up to the uppermost sensor face. non flush sensors, on the other hand, require some free space around the sensing face. Each metal that you’re trying to detect has a different correction factor for an inductive sensor. so if you’re working with aluminum, for example, you’ll want to look for something that has factor 1 or multi metal sensing. if you’re trying to detect copper, factor 1 has the most value. Understanding the difference between flush and non flush proximity sensors is crucial in industrial engineering. each type has its advantages, and the right choice depends on your application’s specific requirements. In a previous blog flush or non flush, looks can be deceiving, jeff mentions the two common housing designs of inductive sensors, flush and non flush. so what does this mean to you when you are applying an inductive or even a capacitive sensor?.

China Flush Non Flush Sensor Manufacturers Flush Non Flush Sensor Understanding the difference between flush and non flush proximity sensors is crucial in industrial engineering. each type has its advantages, and the right choice depends on your application’s specific requirements. In a previous blog flush or non flush, looks can be deceiving, jeff mentions the two common housing designs of inductive sensors, flush and non flush. so what does this mean to you when you are applying an inductive or even a capacitive sensor?. Understanding the different types of inductive sensor is key to making the right decision when it comes time to replace old, broken or faulty parts on your production line. Both flush and non flush sensors fall under the umbrella of inductive proximity sensors, the most common type used in industrial settings for detecting metallic objects. The difference between flush and non flush mountable sensor is as below : flush style sensors actually have a shield that restricts the magnetic field so that it only radiates out of the face of the sensor.

What Is The Difference Between Flush And Non Flush Mountable Inductive Understanding the different types of inductive sensor is key to making the right decision when it comes time to replace old, broken or faulty parts on your production line. Both flush and non flush sensors fall under the umbrella of inductive proximity sensors, the most common type used in industrial settings for detecting metallic objects. The difference between flush and non flush mountable sensor is as below : flush style sensors actually have a shield that restricts the magnetic field so that it only radiates out of the face of the sensor.

What Is The Difference Between Flush And Non Flush Mountable Inductive The difference between flush and non flush mountable sensor is as below : flush style sensors actually have a shield that restricts the magnetic field so that it only radiates out of the face of the sensor.

Comments are closed.