Rule Based Dfm Analysis For Sand Casting Process

Casting Dfm Dfa Analysis Midland Pressure Diecasting Limited Rule based dfm (design for manufacturing) talks about guidelines that has to be followed in order to ensure that the product at the end of the particular manufacturing process is of good. Working with your sand casting supplier at the (design for manufacture) dfm stage will help to identify ways to optimise the part design function, process used and material selection to achieve the desired properties for your casting and project goals.

Casting Dfm Dfa Analysis Midland Pressure Diecasting Limited S defect analysis to know the defect and its causes. production of casting involves various processes like pattern making, molding, core making and melting etc. defects in casting may occur due to different parameters li. In this chapter, we will explore detailed dfm guidelines for five common processes: injection molding, casting, sheet metal fabrication, welding, and cnc machining. these guidelines help mechanical designers create designs that are efficient, cost effective, and feasible to produce. Dfmpro for casting provides design guidelines for draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Dfm, casting system design, simulation and optimization. design of experiments method can be efficiently applied for deciding the optimum settings of process parameters to have minimum.

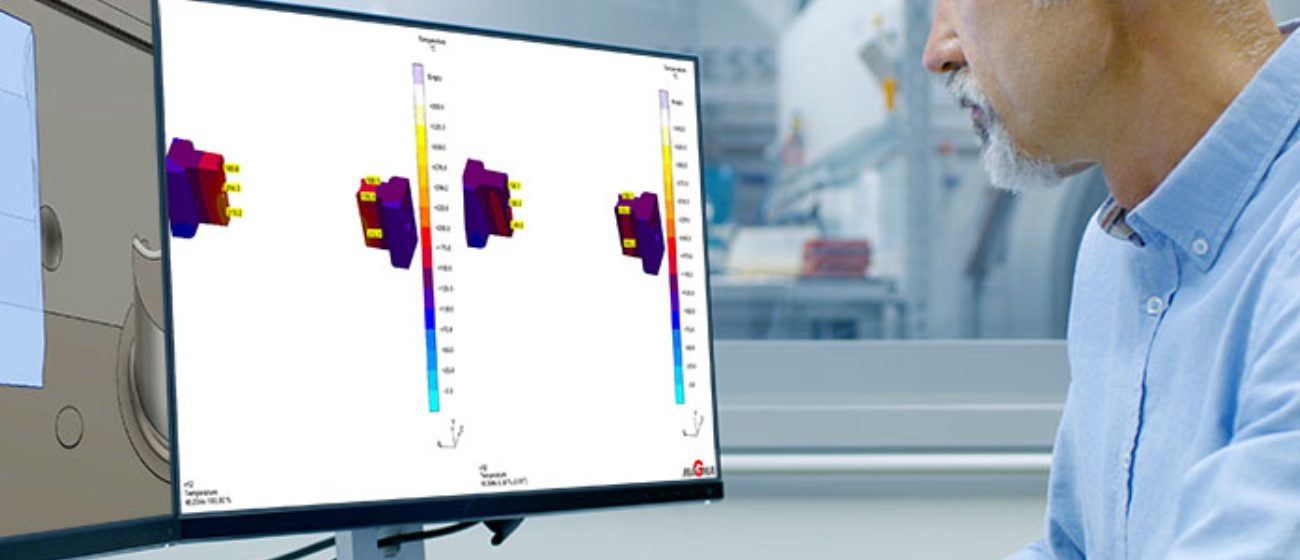

Casting Dfm Dfa Analysis Midland Pressure Diecasting Limited Dfmpro for casting provides design guidelines for draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Dfm, casting system design, simulation and optimization. design of experiments method can be efficiently applied for deciding the optimum settings of process parameters to have minimum. Data from the us government, us industry groups, and uk mass balance profiles facilitate an understanding of sand casting and comparison across manufacturing processes. The powerful hdi analysis of geo designer can help the riser, feeder, insulator sleeve and chill design, specially used for gravity casting. if we compared with other experience formulas and graphic programs, the geo designer approach is more flexible, accurate and easy to use. Sandman® is patented in india, usa, europe, china, brazil, korea and japan. its multivariate analysis correlates green sand properties with casting defects, offering predictive and prescriptive recommendations for process control of system sand properties and additives. This article delves into the process design and simulation analysis of sand casting for complex structural components. we will discuss key aspects such as pouring position selection, parting surface determination, gating system design, and simulation based optimization measures.

Casting Dfm Dfa Analysis Midland Pressure Diecasting Limited Data from the us government, us industry groups, and uk mass balance profiles facilitate an understanding of sand casting and comparison across manufacturing processes. The powerful hdi analysis of geo designer can help the riser, feeder, insulator sleeve and chill design, specially used for gravity casting. if we compared with other experience formulas and graphic programs, the geo designer approach is more flexible, accurate and easy to use. Sandman® is patented in india, usa, europe, china, brazil, korea and japan. its multivariate analysis correlates green sand properties with casting defects, offering predictive and prescriptive recommendations for process control of system sand properties and additives. This article delves into the process design and simulation analysis of sand casting for complex structural components. we will discuss key aspects such as pouring position selection, parting surface determination, gating system design, and simulation based optimization measures.

Casting Dfm Dfa Analysis Midland Pressure Diecasting Limited Sandman® is patented in india, usa, europe, china, brazil, korea and japan. its multivariate analysis correlates green sand properties with casting defects, offering predictive and prescriptive recommendations for process control of system sand properties and additives. This article delves into the process design and simulation analysis of sand casting for complex structural components. we will discuss key aspects such as pouring position selection, parting surface determination, gating system design, and simulation based optimization measures.

Comments are closed.