Pre Load In A Fastener Explained In The Simplest Way Possible Pre

Pre Load In A Fastener Explained In The Simplest Way Possible Pre The term pre load is commonly used in the engineering sector but the meaning of it is not often fully understood. this video sets out to visually explain th. The most common usage is to describe the load applied to a fastener as a result of its being installed, i.e., before any external loads are applied (e.g., tightening the nut on a bolt).

Fastener Clamp Load Preload Resonic Ndt Clamp load or preload refers to the load induced into a fastener by tightening it, crucial for maintaining the integrity of bolted joints. preload must exceed the force attempting to separate the joint, and it can be calculated for each specific bolted connection. Bolt preload ensures that the mating parts stay connected during the operation of the machine. insufficient bolt preload may cause the bolts to become loose, leading to failure of the machine assembly or separation and lateral movement of the mating parts. One of the most critical factors in determining the reliability of a threaded fastener joint is the force the tightened fastener exerts on an assembly, which is known as preload. and. Chnology pre load a primer by laurence claus in the world of fastener engineering, all too often the joint designer gets focused on the wrong things; torque, locking mechanisms, degrees of rotation, and a number of other sundry items, at the expense of focusin.

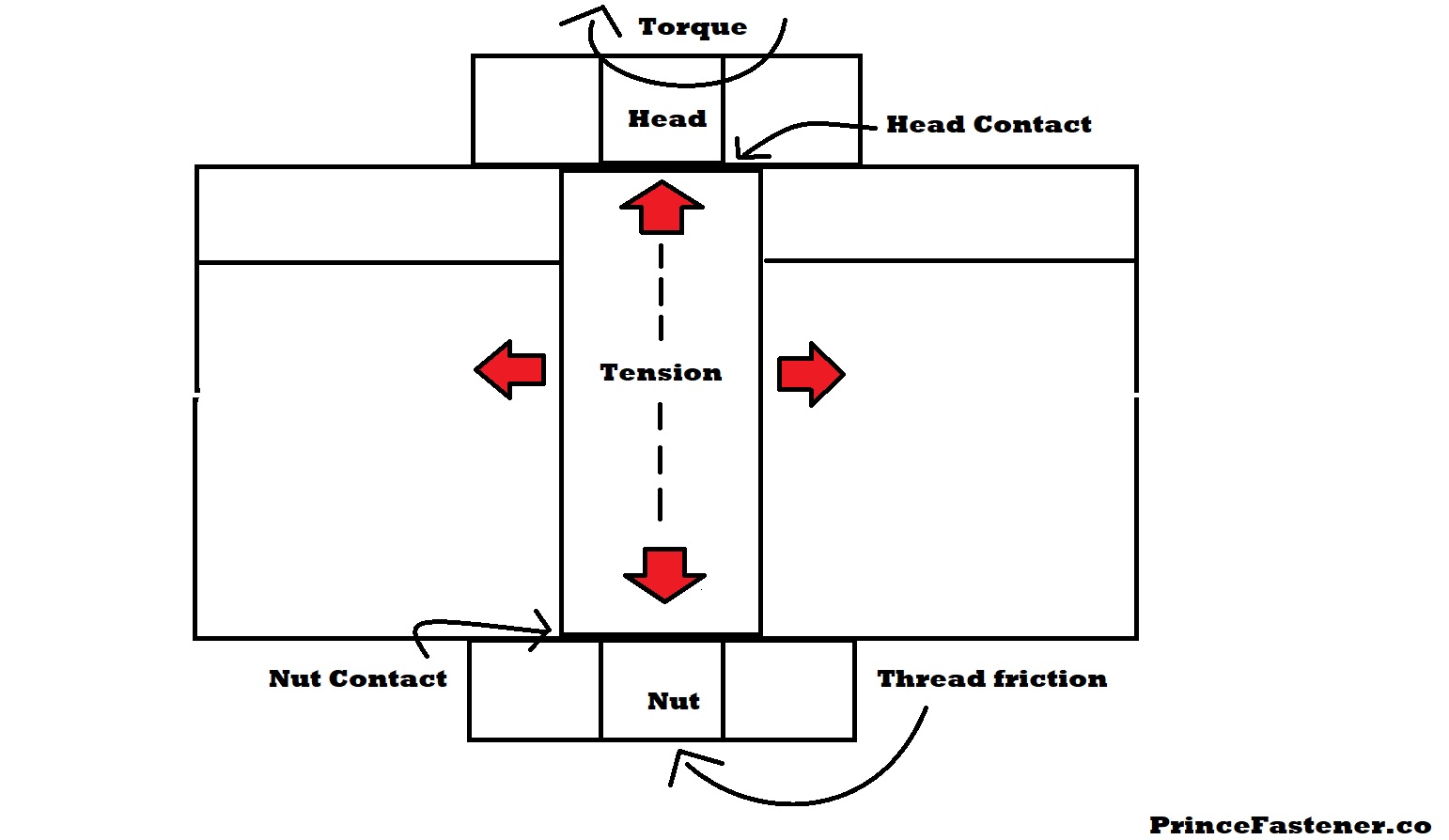

What Are High Tensile Fasteners Prince Fastener One of the most critical factors in determining the reliability of a threaded fastener joint is the force the tightened fastener exerts on an assembly, which is known as preload. and. Chnology pre load a primer by laurence claus in the world of fastener engineering, all too often the joint designer gets focused on the wrong things; torque, locking mechanisms, degrees of rotation, and a number of other sundry items, at the expense of focusin. In the context of securing fasteners, "pre load" refers to the intentional application of a specific amount of axial force or tension to a fastener (such as a bolt or a screw) before it is tightened down to its final torque or clamp load. Bolt preload is a term that refers to the tension created when a nut works with a bolt to hold together two materials. as the tension hits the optimal preload, the working load acting on a bolt is distributed across the assembly, in order to prevent the bolt from bearing the complete load. We generally apply torque via a wrench to the bolt or nut to generate the required tightening load. this tightening load is called preload. preload is defined as the tension created in a fastener when it is tightened. its function is to prevent the slippage and opening of construction parts. A fully tightened bolt can survive in an application that an untightened, or loose bolt, would fail in a matter of seconds. when a load is applied to a joint containing a tightened bolt it does not sustain the full effect of the load but usually only a small part of it.

Why Preload In Bolts Is Important For Fastener Success Mentored Engineer In the context of securing fasteners, "pre load" refers to the intentional application of a specific amount of axial force or tension to a fastener (such as a bolt or a screw) before it is tightened down to its final torque or clamp load. Bolt preload is a term that refers to the tension created when a nut works with a bolt to hold together two materials. as the tension hits the optimal preload, the working load acting on a bolt is distributed across the assembly, in order to prevent the bolt from bearing the complete load. We generally apply torque via a wrench to the bolt or nut to generate the required tightening load. this tightening load is called preload. preload is defined as the tension created in a fastener when it is tightened. its function is to prevent the slippage and opening of construction parts. A fully tightened bolt can survive in an application that an untightened, or loose bolt, would fail in a matter of seconds. when a load is applied to a joint containing a tightened bolt it does not sustain the full effect of the load but usually only a small part of it.

Comments are closed.