Pcba Capabilities Pcb Assembly Process Fastpcb

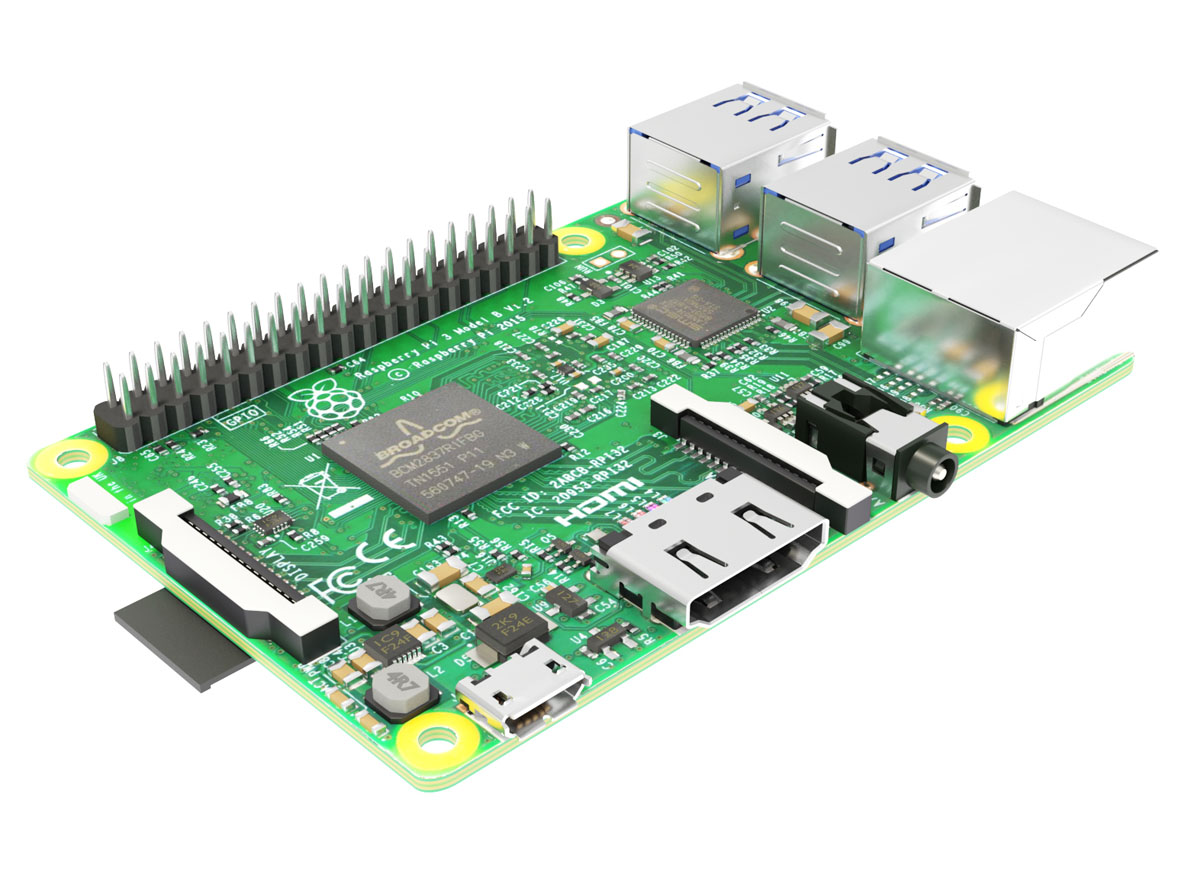

China Customized Pcba Manufacturing Process Manufacturers And Suppliers To put it simply, it is the process of putting together and linking components on a printed circuit board (pcb) to make an operational device. in this article, we’ll explore the different types of pcba, the benefits of using pcba in your designs, and the various applications where pcba is utilized. A pcb is the bare, unpopulated board that provides the physical foundation and electrical connections, while a pcba is the complete, functional assembly with all components installed.

Pcb Assembly Capabilities Pcba meaning – what is pcba? pcba stands for printed circuit board assembly. a pcb is referred to as a pcba when all the required basic electronic components such as resistors, capacitors, ics are all soldered onto it and the board is ready to function as intended. A pcb is a blank circuit board with no electronic components attached, while a pcba is a completed assembly that contains all of the components required for the board to function as needed for the desired application. This article explores what pcba is, its benefits, and the key differences between pcb and pcba. what is pcba? pcba stands for printed circuit board assembly. it refers to the complete assembly of a pcb with all its electronic components soldered and ready to perform its designed function. This guide provides a comprehensive overview of the printed circuit boards assembly (pcba) manufacturing workflow, incorporating real factory practices, industry standards, and critical quality control points at each stage.

Experience Lightning Fast Pcb Assembly This article explores what pcba is, its benefits, and the key differences between pcb and pcba. what is pcba? pcba stands for printed circuit board assembly. it refers to the complete assembly of a pcb with all its electronic components soldered and ready to perform its designed function. This guide provides a comprehensive overview of the printed circuit boards assembly (pcba) manufacturing workflow, incorporating real factory practices, industry standards, and critical quality control points at each stage. Pcba is an acronym for printed circuit board assembly. it is the assembly of electronic components onto a printed circuit board (pcb) and also refers to the output of such assembly or the system produced by the assembly. Pcba stands for printed circuit board assembly, which is the process of assembling various electronic components onto a printed circuit board (pcb) to create a functional electronic device. Pcba stands for printed circuit board assembly, referring to the complete procedure of a bare pcb being subjected to smt assembly or dip plug in. the distinction between pcb and pcba is as follows: pcba = pcb assembly. The pcba process has evolved rapidly over the years, driven by the demand for smaller, more powerful, and more efficient electronic devices. in this article, we have covered the basics of the pcba process, including the different types of pcbs, components, and assembly techniques.

Pcb Assembly Capabilities Fastturnpcbs Pcba is an acronym for printed circuit board assembly. it is the assembly of electronic components onto a printed circuit board (pcb) and also refers to the output of such assembly or the system produced by the assembly. Pcba stands for printed circuit board assembly, which is the process of assembling various electronic components onto a printed circuit board (pcb) to create a functional electronic device. Pcba stands for printed circuit board assembly, referring to the complete procedure of a bare pcb being subjected to smt assembly or dip plug in. the distinction between pcb and pcba is as follows: pcba = pcb assembly. The pcba process has evolved rapidly over the years, driven by the demand for smaller, more powerful, and more efficient electronic devices. in this article, we have covered the basics of the pcba process, including the different types of pcbs, components, and assembly techniques.

Pcb Assembly Process Standard Pcba Procedure Pcba stands for printed circuit board assembly, referring to the complete procedure of a bare pcb being subjected to smt assembly or dip plug in. the distinction between pcb and pcba is as follows: pcba = pcb assembly. The pcba process has evolved rapidly over the years, driven by the demand for smaller, more powerful, and more efficient electronic devices. in this article, we have covered the basics of the pcba process, including the different types of pcbs, components, and assembly techniques.

Pcb Assembly Process Pcba Manufacturing Pcba Process Pcbonline

Comments are closed.