Navigate The Lean Path To Operational Excellence With Data Driven Continuous Improvement

Operational Excellence As A Path To Continuous Improvement Learn how enhancing operational efficiency not only positively impacts your organization's bottom line but also boosts associate engagement and retention. Matrix automation exemplifies how digital transformation aligns with lean and six sigma to redefine operational excellence – spanning all steps in dmaic as well as lean from root cause analysis and just in time (jit) production to continuous flow and takt time optimization.

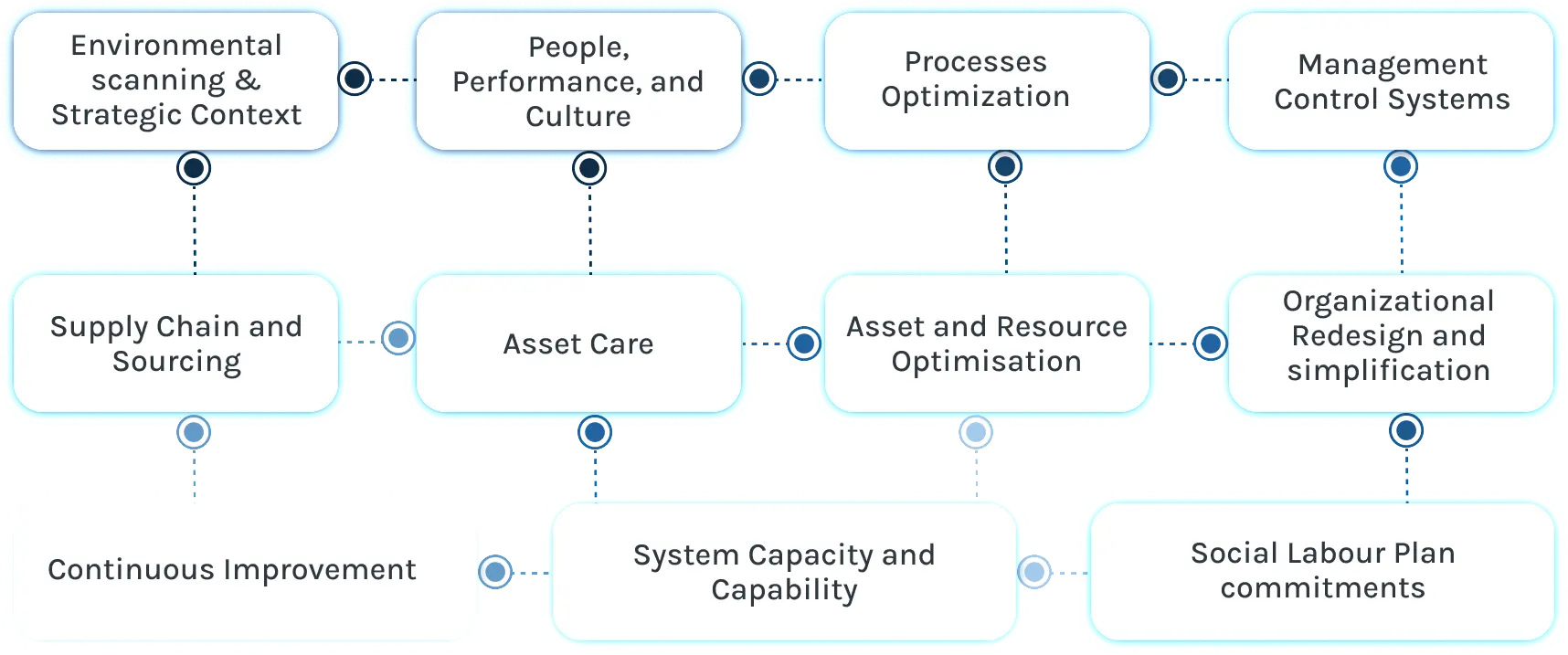

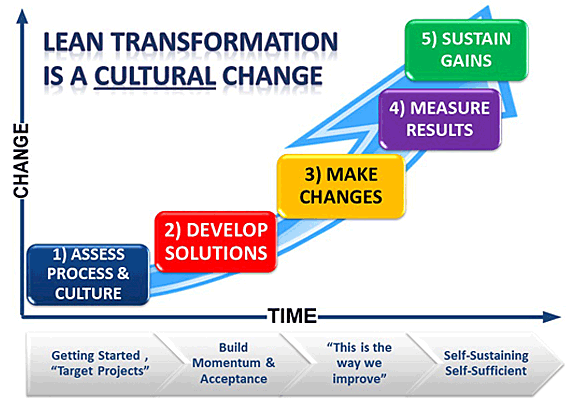

Continuous Improvement Lean And Operational Excellence The Lean practices focus on eliminating waste and improving efficiency, while technology driven strategies leverage ai and data science to enhance operations. the integration of these methodologies allows companies to create a robust operational framework that is both agile and efficient. At its core, lean is about eliminating waste and continuously improving processes. but without the right metrics, how do you know what’s working and what’s not? lean metrics provide. In summary, achieving operational excellence through data driven strategies demands more than just technological upgrades; it necessitates a comprehensive approach encompassing organizational readiness, cultural transformation, and proactive change management. Six sigma methodology enhances data driven process improvement through its structured dmaic framework. this systematic approach aligns perfectly with data driven decision making, providing a proven roadmap for achieving measurable results. the dmaic process consists of five key phases:.

Implementing Lean Management Principles For Operational Excellence In summary, achieving operational excellence through data driven strategies demands more than just technological upgrades; it necessitates a comprehensive approach encompassing organizational readiness, cultural transformation, and proactive change management. Six sigma methodology enhances data driven process improvement through its structured dmaic framework. this systematic approach aligns perfectly with data driven decision making, providing a proven roadmap for achieving measurable results. the dmaic process consists of five key phases:. Discover how lean six sigma transforms raw data into actionable insights for strategic decision making. learn to enhance business operations with data driven methodologies and achieve operational excellence. Let’s explore the most powerful techniques used by high performing organizations to achieve operational excellence. 1. lean thinking: eliminate waste, create value. originating from the toyota production system, lean thinking is about delivering maximum customer value with minimal waste. Continuous improvement is most effective when data informs decisions. gathering data from operations, customer feedback, and performance metrics helps identify areas for improvement and evaluate the impact of changes. This powerful methodology provides a structured approach to process improvement, enabling organizations to enhance performance, reduce costs, and achieve higher customer satisfaction. this article explores how lean six sigma training serves as a pathway to operational excellence.

Data Driven Continuous Improvement Discover how lean six sigma transforms raw data into actionable insights for strategic decision making. learn to enhance business operations with data driven methodologies and achieve operational excellence. Let’s explore the most powerful techniques used by high performing organizations to achieve operational excellence. 1. lean thinking: eliminate waste, create value. originating from the toyota production system, lean thinking is about delivering maximum customer value with minimal waste. Continuous improvement is most effective when data informs decisions. gathering data from operations, customer feedback, and performance metrics helps identify areas for improvement and evaluate the impact of changes. This powerful methodology provides a structured approach to process improvement, enabling organizations to enhance performance, reduce costs, and achieve higher customer satisfaction. this article explores how lean six sigma training serves as a pathway to operational excellence.

Operational Excellence Lean And Continuous Improvement Continuous improvement is most effective when data informs decisions. gathering data from operations, customer feedback, and performance metrics helps identify areas for improvement and evaluate the impact of changes. This powerful methodology provides a structured approach to process improvement, enabling organizations to enhance performance, reduce costs, and achieve higher customer satisfaction. this article explores how lean six sigma training serves as a pathway to operational excellence.

Comments are closed.