Methods To Streamline Production Implementation Of Cost Efficiency

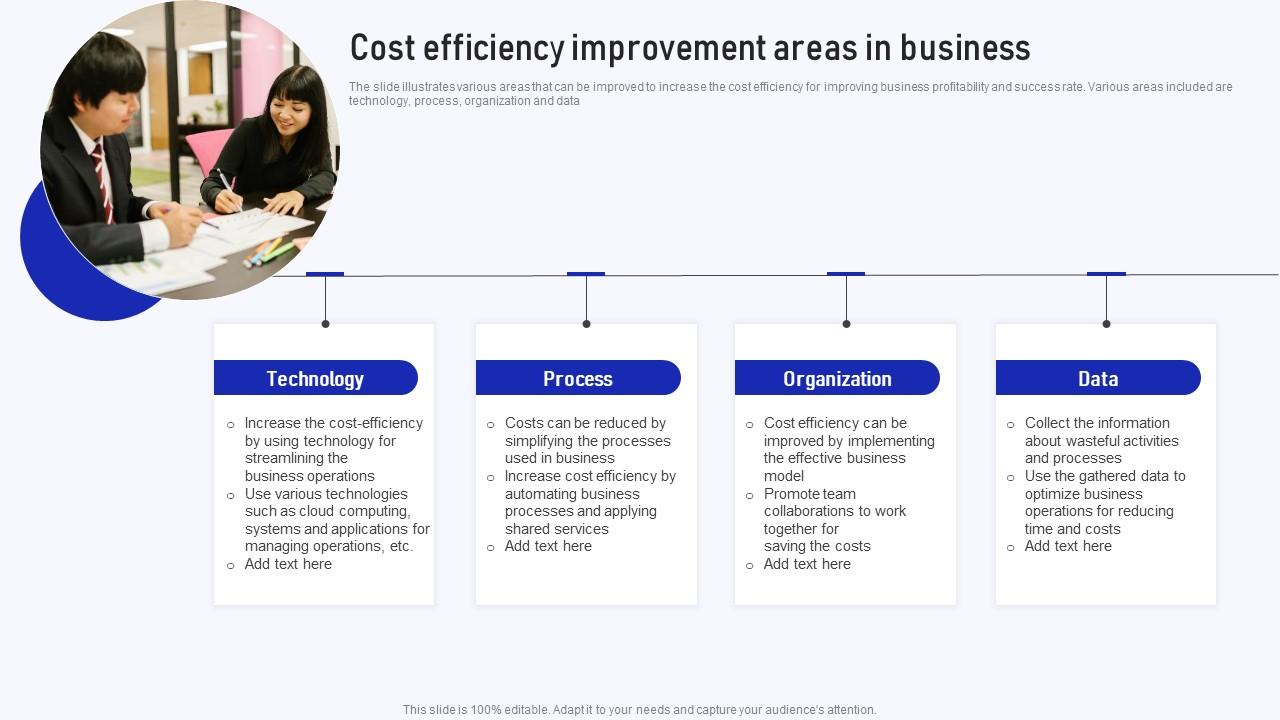

Methods To Streamline Production Implementation Of Cost Efficiency In this segment, we will discuss some of the benefits and risks of process streamlining for cost efficiency, and provide some examples and best practices to guide the implementation. By streamlining processes, minimizing waste, and optimizing resource utilization, you can lower your expenses on materials, labor, and energy. consequently, this cost savings can be reinvested into the business to drive growth, innovation, and competitive advantage.

Key Techniques To Enhance Cost Efficiency Methods Streamline Production Reduced costs: one of the best ways to save money in manufacturing is to streamline processes. reducing waste, labor, time, errors or rework on the manufacturing line can often benefit the bottom line nearly immediately. One effective approach is implementing lean manufacturing principles, which focus on minimizing waste while maximizing productivity. this involves analyzing workflows to identify bottlenecks and redundancies, allowing companies to streamline operations and allocate resources more effectively. By continuously thinking about and streamlining processes to improve operational efficiency, businesses can identify areas to reduce waste, lower expenses, and invest in long term opportunities. Learn how manufacturers can streamline operations, cut costs, and improve efficiency with actionable strategies, smart technology, and real world insights.

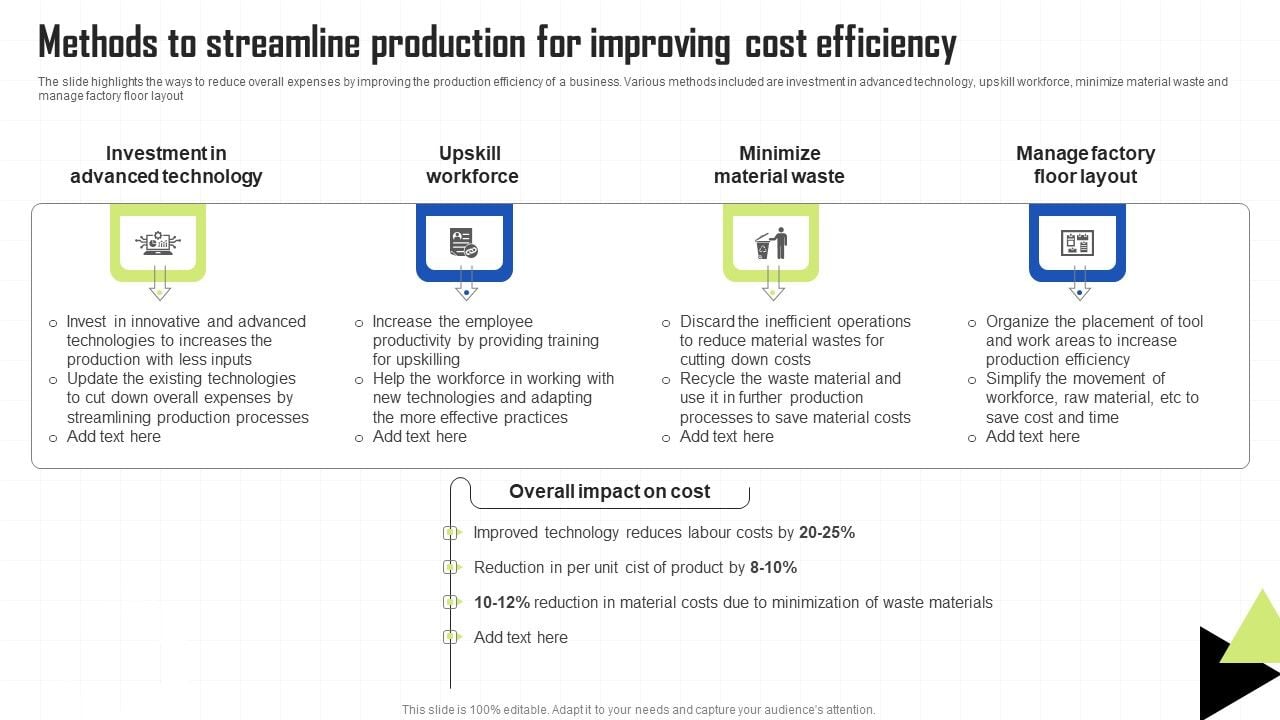

Methods To Streamline Production For Improving Cost Efficiency Cost By continuously thinking about and streamlining processes to improve operational efficiency, businesses can identify areas to reduce waste, lower expenses, and invest in long term opportunities. Learn how manufacturers can streamline operations, cut costs, and improve efficiency with actionable strategies, smart technology, and real world insights. Here are 11 steps you can follow to streamline production and improve your overall efficiency: 1. improve quality. it's important that you make improvements to quality throughout the entire process. In this section, we will explore various strategies aimed at optimizing production processes, eliminating bottlenecks, and maximizing resource utilization. by implementing these strategies, organizations can not only improve operational efficiency but also drive profitability and sustainable growth. Discover effective process optimisation techniques to enhance efficiency and productivity in your organization. learn how to identify bottlenecks, streamline workflows, and implement innovative solutions for continuous improvement. Some of the methodologies that provide a guideline in identifying inefficiencies and implementing solutions to streamline for operational efficiency include lean, six sigma, and kaizen.

Cost Efficiency Strategies For Reducing Methods To Streamline Here are 11 steps you can follow to streamline production and improve your overall efficiency: 1. improve quality. it's important that you make improvements to quality throughout the entire process. In this section, we will explore various strategies aimed at optimizing production processes, eliminating bottlenecks, and maximizing resource utilization. by implementing these strategies, organizations can not only improve operational efficiency but also drive profitability and sustainable growth. Discover effective process optimisation techniques to enhance efficiency and productivity in your organization. learn how to identify bottlenecks, streamline workflows, and implement innovative solutions for continuous improvement. Some of the methodologies that provide a guideline in identifying inefficiencies and implementing solutions to streamline for operational efficiency include lean, six sigma, and kaizen.

Methods To Streamline Production For Improving Cost Key Strategies For Discover effective process optimisation techniques to enhance efficiency and productivity in your organization. learn how to identify bottlenecks, streamline workflows, and implement innovative solutions for continuous improvement. Some of the methodologies that provide a guideline in identifying inefficiencies and implementing solutions to streamline for operational efficiency include lean, six sigma, and kaizen.

Cost Efficiency Improvement Areas Implementation Of Cost Efficiency

Comments are closed.