How To Print Transparent Models Polymaker

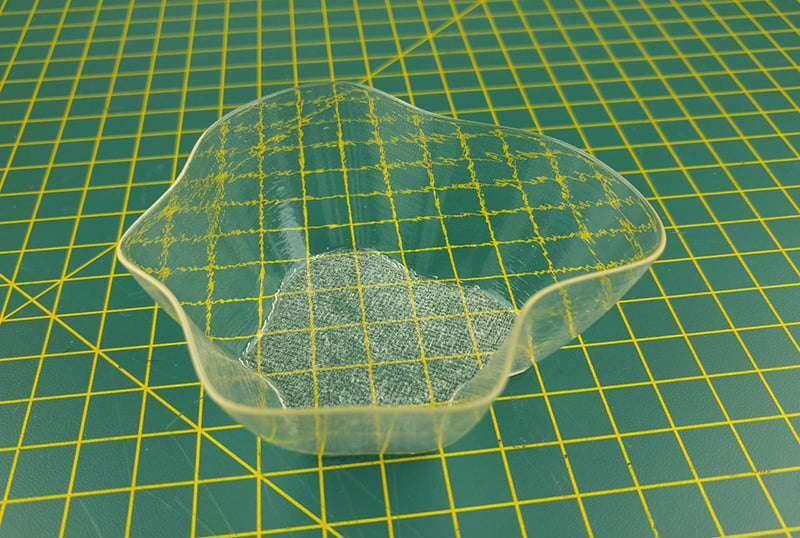

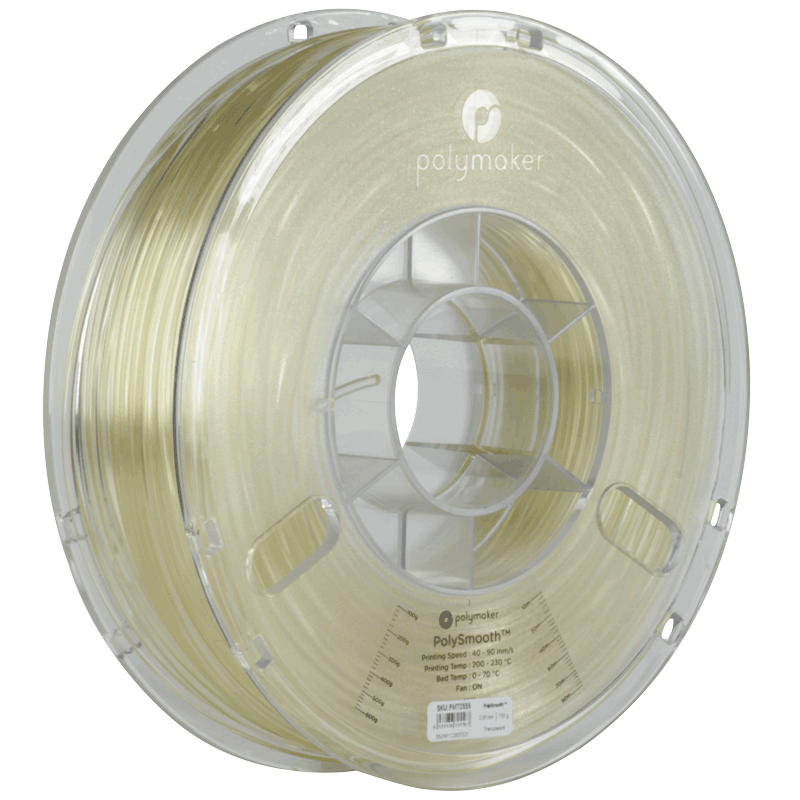

How To Print Transparent Models Polymaker Polysmooth™ transparent can create some of the highest transparency parts that can be printed with fff fdm technology. following our tips below should help you on your way to creating highly transparent parts with glass like clarity. Perfectly clear 3d printed parts are possible with polysmooth™ and here is the story of one of our customers. mattias has shared with us his process creating a pair of lenses for the kitchen fan lights.

How To Print Transparent Models Polymaker Knowing these tips, you ought to be able to print your own transparent models seen in the pictures above. lulzbot has just released their polycast™ bundles alongside a comprehensive guide for turning your 3d printed parts into metal parts. This article will guide how to slice and print a model as transparent as possible with transparent or translucent pla petg filaments. dry the filament before use: moisture in the filament can cause bubbles and voids in the extruded lines, which can affect the transparency of the printed part. Hey gang, tim here at core electronics and today i'm showing you how to post process 3d prints to make them perfectly transparent. your friends won't believe the results and your family won't understand, but this guide will tell you all the secrets to post process a fused filament fabricated 3d printed component to the point of looking like glass. The only way to counter this is by a lot of sanding and polishing. then you have the problem with the infill. unless the print is 100% infill, the only thing you'll see is the infill pattern. so any print will take ages, and require intense post processing.

How To Print Transparent Models Polymaker Hey gang, tim here at core electronics and today i'm showing you how to post process 3d prints to make them perfectly transparent. your friends won't believe the results and your family won't understand, but this guide will tell you all the secrets to post process a fused filament fabricated 3d printed component to the point of looking like glass. The only way to counter this is by a lot of sanding and polishing. then you have the problem with the infill. unless the print is 100% infill, the only thing you'll see is the infill pattern. so any print will take ages, and require intense post processing. But polymaker makes a filament called “polysmooth” that you can get in clear, and you postprocess to improve the clarity by using a mist bottle with alcohol lightly a few times on it, after printing. basically the same as doing acetone vapor smoothing on abs prints, but far less toxic. One method to do this is by using a specialized filament called the polysmooth by polymaker, then use a high strength of isopropyl alcohol to gradually smooth and dissolve the outer surface, leading to a very clear 3d print. There are many different models available for these tests, but the simplest way is to use orcaslicer, which offers many tests in a single menu. there is a detailed wiki to explain how to interpret and use the results. For me the problem seems to be polymaker petg. some have had good luck with it. i've got 4 different rolls including clear and have never gotten a clean print on my stock mk3s . my $10 cheapie rolls of jayo from aliexpress run circles around that stuff.

Comments are closed.