How To Optimize Cnc Machining For Rapid Tooling

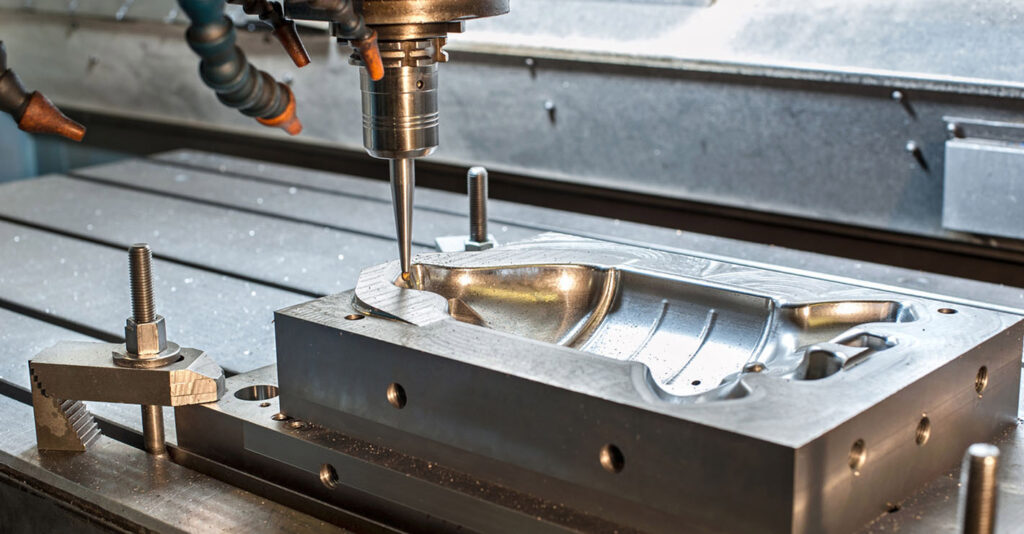

Rapid Tooling Cnc Shop Floor This guide covers the essential aspects of cnc machining optimization including tooling, parameters, machine maintenance, quality control and more. learn how to prolong tool life, boost productivity, lower costs and ensure top part quality through continuous improvement best practices. In this blog, we’re going to break down some simple, actionable tips to help you in optimizing cnc machining process. these tips are easy to understand, and whether you’re new to cnc machining or have years of experience, they’ll help you get the most out of your equipment.

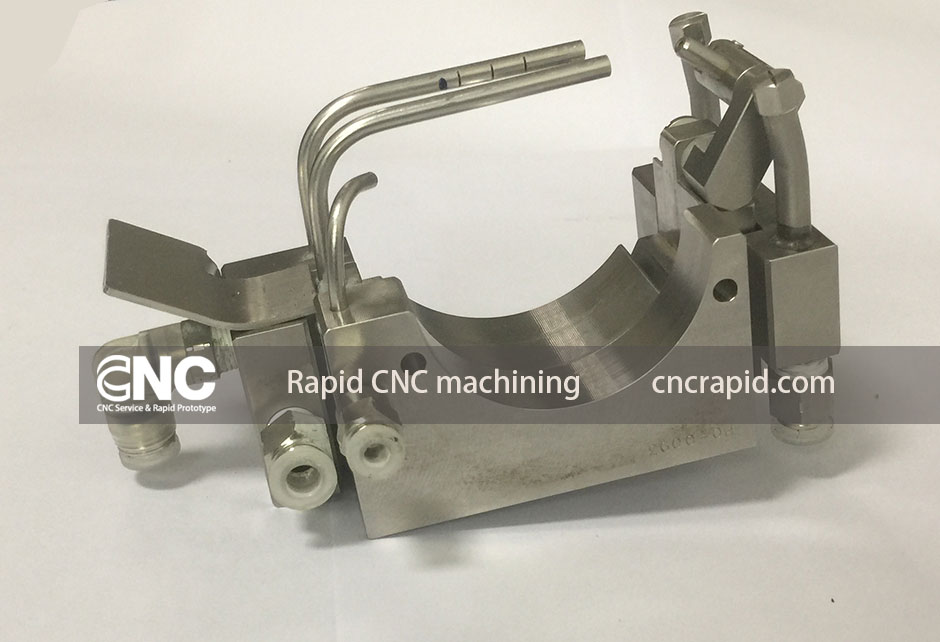

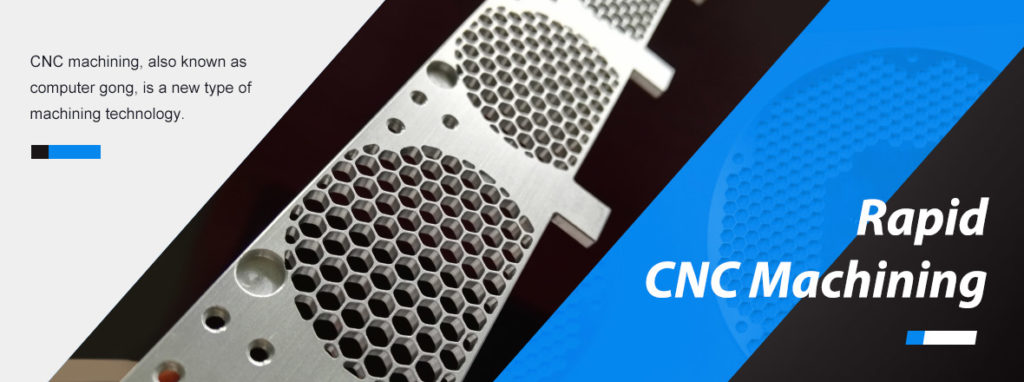

Rapid Cnc Machining Dakings Rapid Manufacturing Co Limited Learn how cnc factories optimize production efficiency for rapid delivery with proven, systematic strategies and detailed technical insights. Improving cnc machining efficiency slashes costs, speeds up delivery, and sharpens your competitive edge. this guide shares 10 practical tips, from refining tool paths to leveraging simulation software, to elevate your process. Efficient cnc machining requires a harmonious blend of state of the art technology, skilled craftsmanship, and robust workflows. across sources, common themes emerge: optimization of programming, tooling selection, maintenance protocols, and workflow management. Optimizing speed and feed in cnc machining can dramatically increase efficiency, prolong tool life, and enhance surface finish. dive into a refined guide packed with data backed methods, practical steps, and real world best practices to achieve peak machining performance.

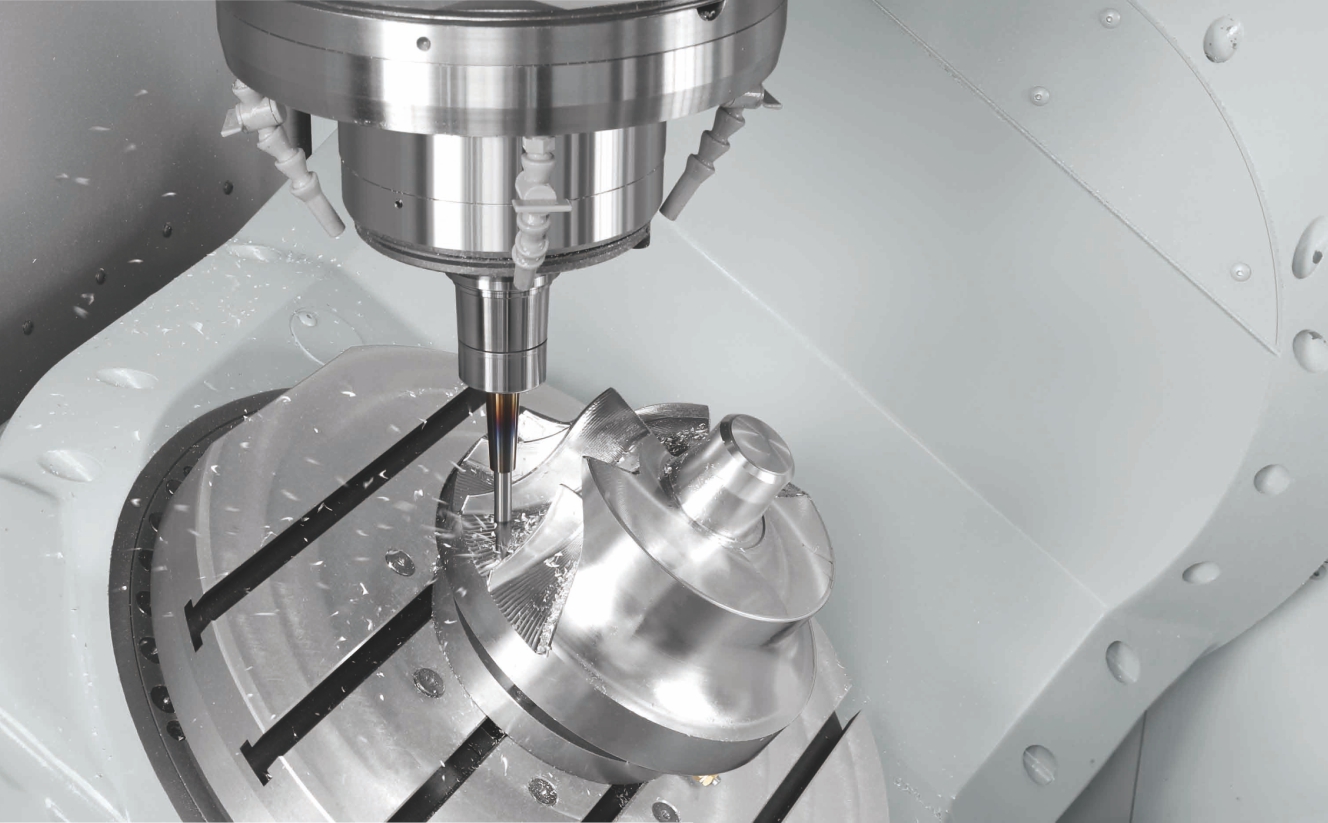

Rapid Cnc Machining Cnc Prototyping Service Cncrapid Efficient cnc machining requires a harmonious blend of state of the art technology, skilled craftsmanship, and robust workflows. across sources, common themes emerge: optimization of programming, tooling selection, maintenance protocols, and workflow management. Optimizing speed and feed in cnc machining can dramatically increase efficiency, prolong tool life, and enhance surface finish. dive into a refined guide packed with data backed methods, practical steps, and real world best practices to achieve peak machining performance. In this blog, we’ll explore practical tips on how to optimize your cnc machining designs to achieve the best balance between speed and accuracy. Discover design optimization techniques for cnc rapid machining that improve manufacturability, reduce costs, and accelerate your timeline. Optimize tool selection and cutting parameters. choose the right tools based on the material's properties. for instance, when machining aluminum alloys, prioritize carbide tools. for cutting parameters, during roughing, you can increase the cutting depth and feed rate to reduce the number of passes. If you’re running a machine shop, freelancing, or even just learning to write g code in your garage, this guide will walk you through 12 cnc programming tips that can actually boost your machining speed, without sacrificing quality or tool life. these tips come from experience, mistakes, late nights, and a lot of learning the hard way.

Guide To Rapid Tooling Formlabs In this blog, we’ll explore practical tips on how to optimize your cnc machining designs to achieve the best balance between speed and accuracy. Discover design optimization techniques for cnc rapid machining that improve manufacturability, reduce costs, and accelerate your timeline. Optimize tool selection and cutting parameters. choose the right tools based on the material's properties. for instance, when machining aluminum alloys, prioritize carbide tools. for cutting parameters, during roughing, you can increase the cutting depth and feed rate to reduce the number of passes. If you’re running a machine shop, freelancing, or even just learning to write g code in your garage, this guide will walk you through 12 cnc programming tips that can actually boost your machining speed, without sacrificing quality or tool life. these tips come from experience, mistakes, late nights, and a lot of learning the hard way.

Rapid Cnc Machining And Prototyping Services China Essaii Optimize tool selection and cutting parameters. choose the right tools based on the material's properties. for instance, when machining aluminum alloys, prioritize carbide tools. for cutting parameters, during roughing, you can increase the cutting depth and feed rate to reduce the number of passes. If you’re running a machine shop, freelancing, or even just learning to write g code in your garage, this guide will walk you through 12 cnc programming tips that can actually boost your machining speed, without sacrificing quality or tool life. these tips come from experience, mistakes, late nights, and a lot of learning the hard way.

Comments are closed.