Factories May Be Leaving China But Trade Ties Are Stronger Than They

Us China Trade War Forces Some Chinese Factories To Move To Southeast A new report from the world economic forum identifies factories of the future that are reshaping manufacturing through the early adoption of game changing technologies. Why strive for industry 4.0 building the factories of the future microfactories certainly look like the factories of the future, but how does a manufacturer know if it should change its entire operational setup in this way? a transformation of this scale requires a comprehensive overview of processes to ensure the right changes are made.

As Trade War Hits China Factories See Slowest Growth Since 2002 Geneva, switzerland, 14 january 2025 – the world economic forum announces today that 17 innovative industrial sites have joined the global lighthouse network, expanding the community to 189 leading production facilities and value chains that harness digital technologies at scale to achieve exceptional performance in productivity, supply chain resilience, customer centricity, sustainability. Current tariffs and trade tensions are causing some us companies to rethink investments in china, a survey by the us china business council found. 10 new manufacturing sites have joined the world economic forum’s global lighthouse network. there are now 54 ‘lighthouses’, the world’s most advanced factories, which are leading the way in the adoption of fourth industrial revolution technologies. as well as increasing speed and productivity of operations, they are also committed to upskilling the workforce and boosting their eco. Ai is transforming factories, optimizing production, cutting costs and boosting sustainability – the global lighthouse network provides examples.

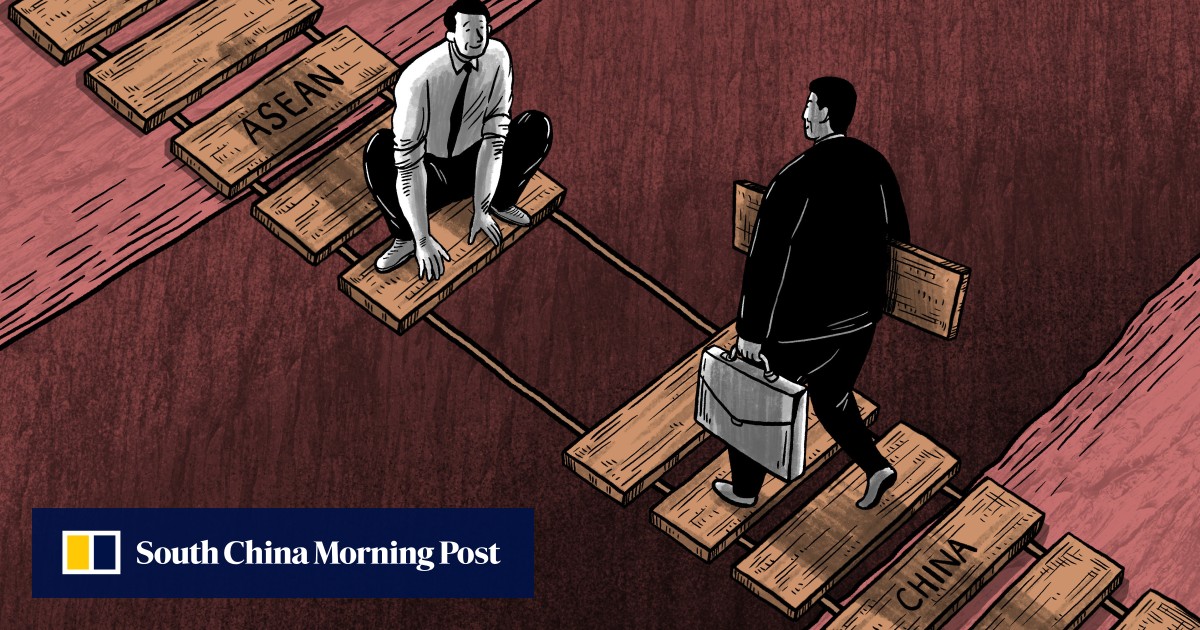

China Eyes Asean Trade Ties But Members Fear Geopolitical Trap As Us 10 new manufacturing sites have joined the world economic forum’s global lighthouse network. there are now 54 ‘lighthouses’, the world’s most advanced factories, which are leading the way in the adoption of fourth industrial revolution technologies. as well as increasing speed and productivity of operations, they are also committed to upskilling the workforce and boosting their eco. Ai is transforming factories, optimizing production, cutting costs and boosting sustainability – the global lighthouse network provides examples. From ai powered autonomous production lines and digital twins that simulate entire supply chains to next gen robotics, manufacturers are eager to leverage frontier innovations to build intelligent, agile and resilient operations. Global challenges are rewiring supply chains and manufacturing companies are rethinking their operations. from brazil to singapore, here's how six countries are managing the shift. First announced in 2015, made in china 2025 (mic2025) set the tone and tempo of china’s industrial ambitions. today, this stategy is entering a new phase — an ai augmented, green energy powered, self reliance oriented transformation of the world’s most formidable industrial base. the question is no longer whether china can innovate, but what kind of innovation ecosystem it is building. Connected factories track the location of labour, materials, machines, and moveable assets in real time. iiot digitizes the production environment by integrating the manufacturing execution system and enterprise resource planning system with embedded devices and process instruments for real time communication.

Comments are closed.