Enhance Defect Detection Systems Accuracy With Ai Powered Image

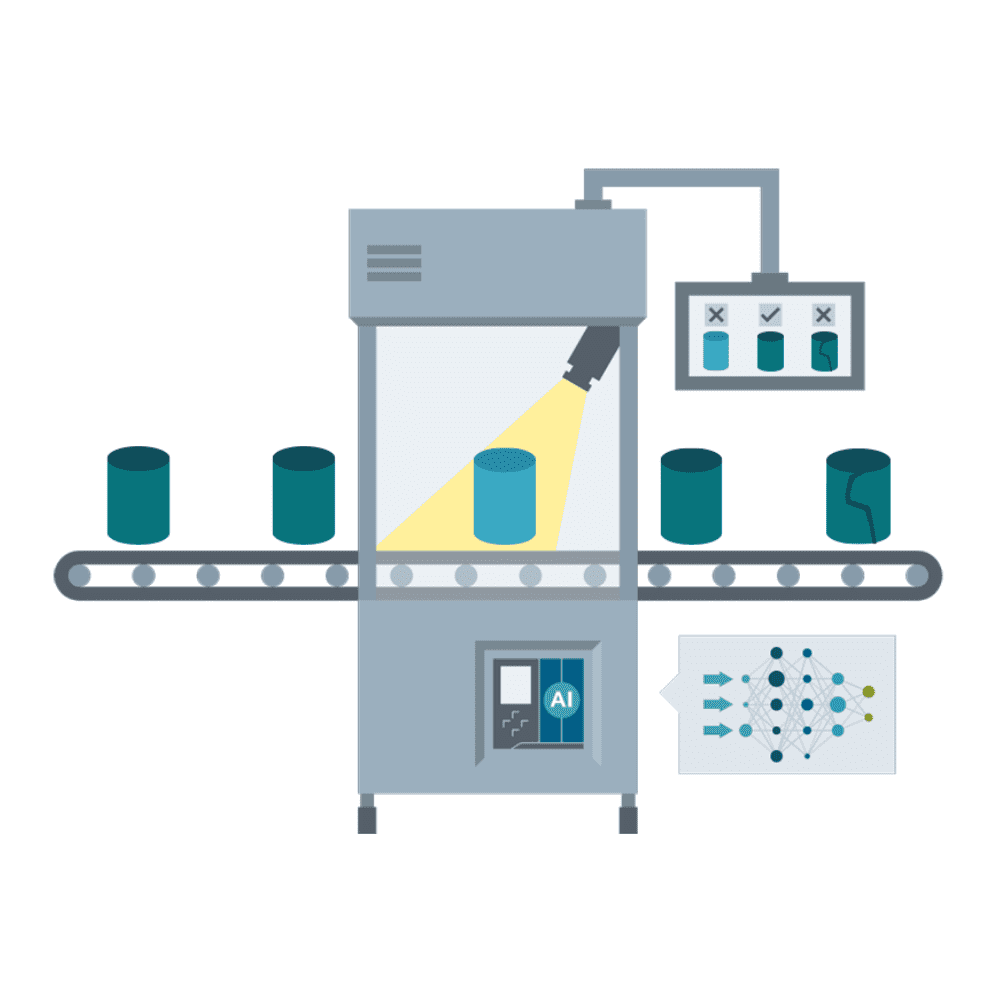

Ai Powered Defect Detection Inspekt Ai Discover how ai powered image annotation transforms defect detection across industries. learn about effective image labeling techniques and data labeling services that boost accuracy and efficiency of defect detection systems. With ai on their side, manufacturers can spot defects early, boost overall quality, and save both time and money. in this blog, we’ll explain how ai powered visual inspection improves defect detection and explain how to integrate smart inspection solutions effectively.

Ai Powered Defect Detection Inspekt Ai Future trends and innovations in ai powered defect detection systems hold the promise of enhancing defect detection capabilities, improving product quality, and driving operational efficiency in manufacturing environments. Ai powered visual inspection systems deliver unparalleled accuracy in defect detection. these systems use advanced algorithms and ai image processing to identify even the smallest irregularities that human inspectors might overlook. Specifically, ai powered image recognition is offering unprecedented levels of accuracy and efficiency. by leveraging machine learning models, image recognition apis can automatically. The adoption of ai powered defect detection offers a multitude of benefits for manufacturers seeking to enhance product quality and operational efficiency. one of the primary advantages is increased accuracy and reliability in defect detection.

Ai Powered Defect Detection Inspekt Ai Specifically, ai powered image recognition is offering unprecedented levels of accuracy and efficiency. by leveraging machine learning models, image recognition apis can automatically. The adoption of ai powered defect detection offers a multitude of benefits for manufacturers seeking to enhance product quality and operational efficiency. one of the primary advantages is increased accuracy and reliability in defect detection. Ai powered anomaly detection is revolutionizing quality control by enhancing accuracy in defect identification, reducing operational costs through automation and providing real time insights for proactive quality management. Detect and resolve defects in real time with ai powered visual inspection. ai defect detection improve product quality, cut costs, and scale faster across all production lines. In defect detection, ai algorithms are trained to analyze images, data, or sensor inputs to identify abnormalities or deviations from standards. this capability allows ai to detect defects in manufacturing processes, product assembly lines, or even in software development. Implementing an edge ai powered computer vision system for defect detection requires careful planning and execution. this guide breaks down the process into four key phases, offering practical steps and considerations for each.

Ai Driven Defect Detection 5 Ways To Improve Quality Ai powered anomaly detection is revolutionizing quality control by enhancing accuracy in defect identification, reducing operational costs through automation and providing real time insights for proactive quality management. Detect and resolve defects in real time with ai powered visual inspection. ai defect detection improve product quality, cut costs, and scale faster across all production lines. In defect detection, ai algorithms are trained to analyze images, data, or sensor inputs to identify abnormalities or deviations from standards. this capability allows ai to detect defects in manufacturing processes, product assembly lines, or even in software development. Implementing an edge ai powered computer vision system for defect detection requires careful planning and execution. this guide breaks down the process into four key phases, offering practical steps and considerations for each.

Ai Defect Detection Kit In defect detection, ai algorithms are trained to analyze images, data, or sensor inputs to identify abnormalities or deviations from standards. this capability allows ai to detect defects in manufacturing processes, product assembly lines, or even in software development. Implementing an edge ai powered computer vision system for defect detection requires careful planning and execution. this guide breaks down the process into four key phases, offering practical steps and considerations for each.

Ai Defect Detection Kit

Comments are closed.