Difference Between Plc And Scada Automation Community

Difference Between Plc And Scada Automation Community In this post, we’ll break down the differences between plc and scada, show how they support one another in automation environments, and explain why understanding both is key to building smarter, more efficient systems. Discover the key difference between plc and scada in industrial automation. explore the roles of hardware plcs and software scada systems.

Difference Between Plc And Scada Automation Community Engineers and operators can make informed decisions when selecting and implementing these technologies by understanding the differences between plc and scada systems, their components, programming languages, communication protocols, and applications. In the following article, we will explain the main differences between plc and scada in order to help you determine when to apply technology or not. Plcs are microprocessor based controllers that are programmed to carry out specific duties, such as machine and process control. on the other hand, scada systems are used to monitor and control large scale operations, such as those in power plants and water treatment facilities. This access industrial automation blog post will explain the differences between scada and plcs. we’ll also shed some light on why you may be confused after reading a few different explanations online.

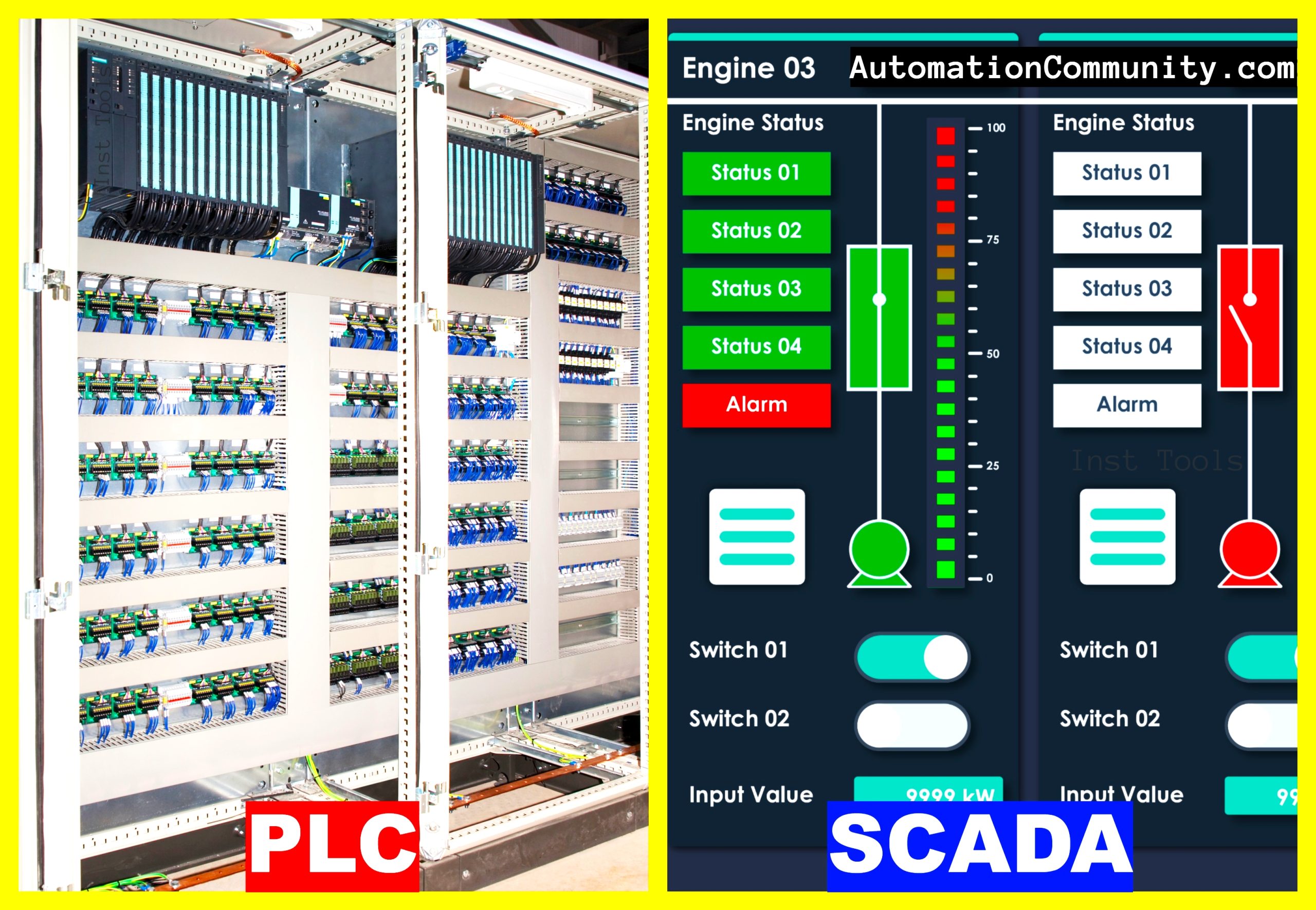

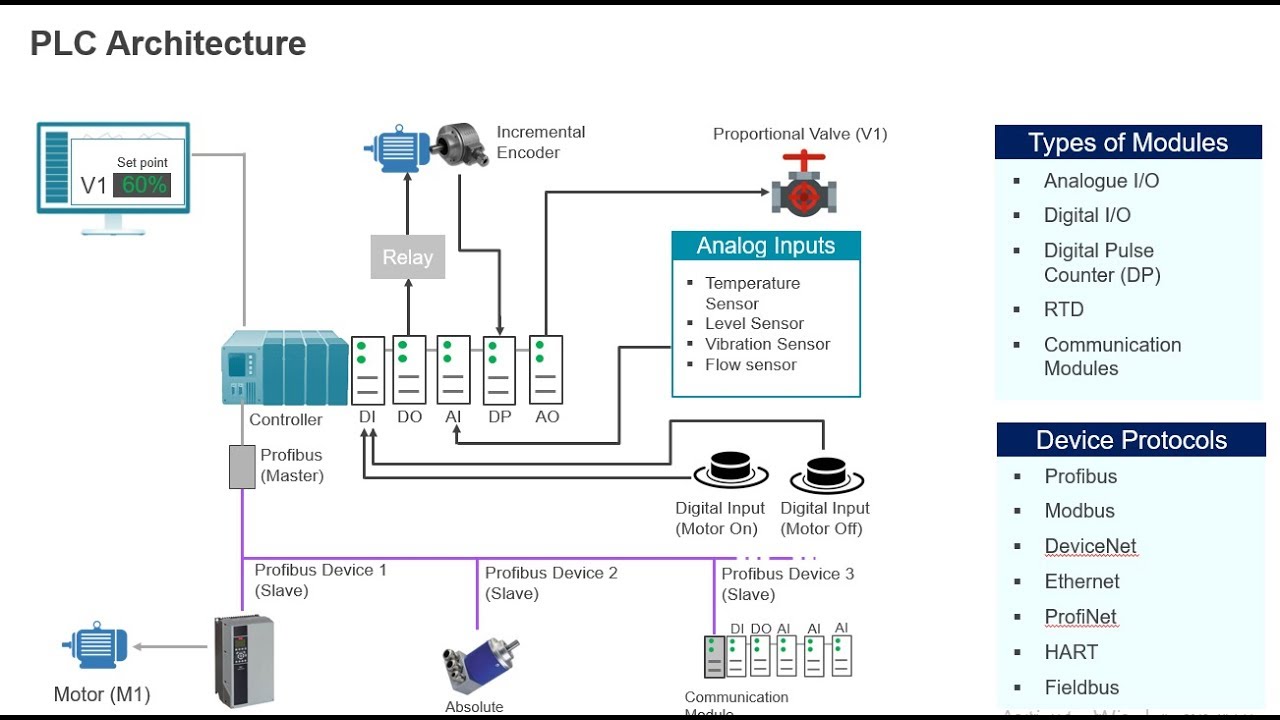

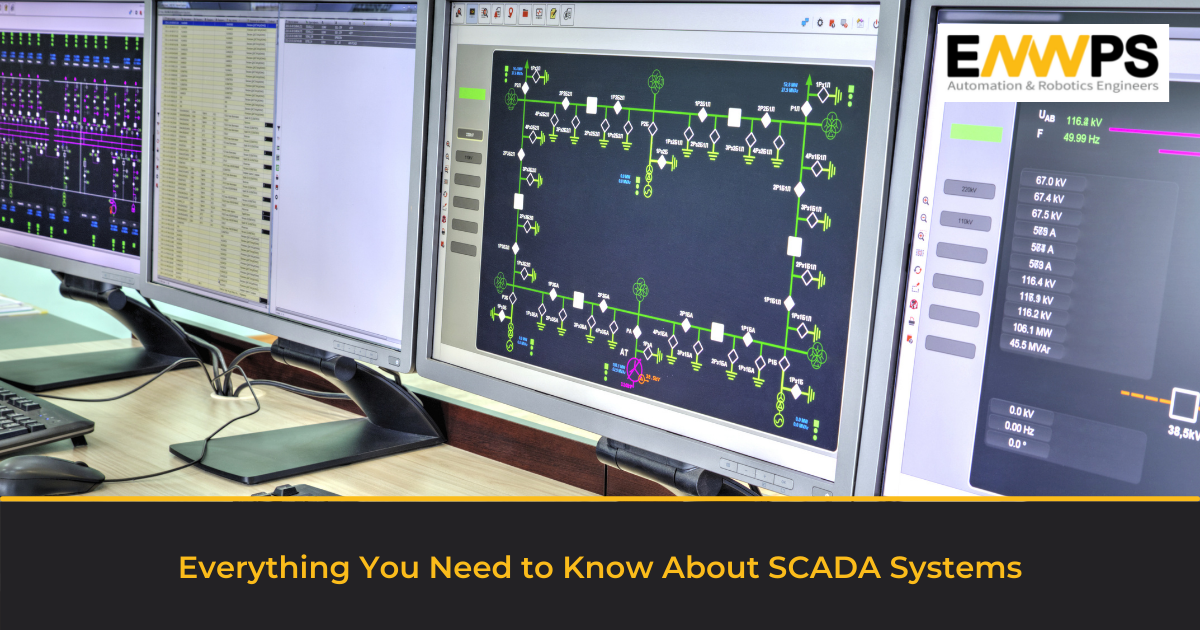

Difference Between Plc And Scada Automation Community Plcs are microprocessor based controllers that are programmed to carry out specific duties, such as machine and process control. on the other hand, scada systems are used to monitor and control large scale operations, such as those in power plants and water treatment facilities. This access industrial automation blog post will explain the differences between scada and plcs. we’ll also shed some light on why you may be confused after reading a few different explanations online. A commonly asked question of people who are new in the control engineering world is just that–“what is the difference between plc and scada?” the difference between them is that the plc is hardware based and scada is software based. Learn the key differences between scada and plc systems, how they work together, and why both are essential for industrial automation and monitoring. While scada systems and plcs are both essential to industrial automation, they have distinct roles and characteristics. functionality: scada systems focus on monitoring and data acquisition, while plcs are primarily used for control tasks. Scada is the preferred choice for large scale operations, whereas plcs are better for smaller, more specific control tasks. to summarise, both scada and plc play critical roles in the industrial control process, and each has its own set of advantages and disadvantages.

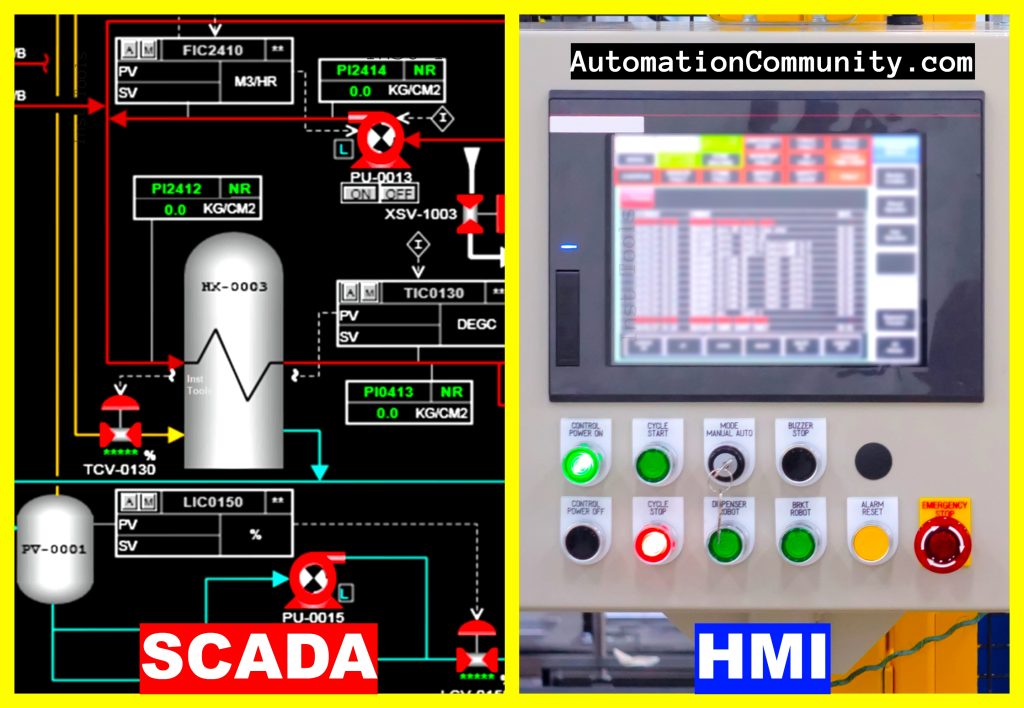

Difference Between Scada And Hmi Automation Community A commonly asked question of people who are new in the control engineering world is just that–“what is the difference between plc and scada?” the difference between them is that the plc is hardware based and scada is software based. Learn the key differences between scada and plc systems, how they work together, and why both are essential for industrial automation and monitoring. While scada systems and plcs are both essential to industrial automation, they have distinct roles and characteristics. functionality: scada systems focus on monitoring and data acquisition, while plcs are primarily used for control tasks. Scada is the preferred choice for large scale operations, whereas plcs are better for smaller, more specific control tasks. to summarise, both scada and plc play critical roles in the industrial control process, and each has its own set of advantages and disadvantages.

Difference Between Plc Scada Hmi Rtu And Dcs Control 54 Off While scada systems and plcs are both essential to industrial automation, they have distinct roles and characteristics. functionality: scada systems focus on monitoring and data acquisition, while plcs are primarily used for control tasks. Scada is the preferred choice for large scale operations, whereas plcs are better for smaller, more specific control tasks. to summarise, both scada and plc play critical roles in the industrial control process, and each has its own set of advantages and disadvantages.

Understanding The Difference Between Plc And Scada 46 Off

Comments are closed.