Decoupling Point Explained What It Is And How To Use It

Customer Decoupling Point Pdf The decoupling point is the last point in the supply chain where inventory is held. this is the point where the forecast based production or procurement process separates from the one based on confirmed customer orders. Decoupling inventory operates by identifying key stages in the production process that are susceptible to delays or disruptions. once these critical junctures are pinpointed, additional stocks of necessary materials or components are strategically positioned at these points.

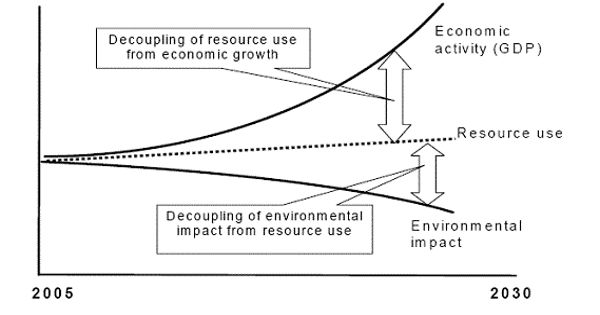

Decoupling Point Pdf Pdf Any supply chain or manufacturing process needs decoupling points where inventory is kept. this inventory serves 2 purposes: inventory dampens supply and demand variability. inventory divides the total lead time. things don’t always go as planned, both on the supply and the demand sides. A decoupling point is a strategic point in the supply chain where materials or components are separated for individual shipment. decoupling points are used to mitigate risk and optimize the supply chain. “the point in the product axis to which the customer’s order penetrates. it is where order driven and the forecast driven activities meet. as a rule, the decoupling point coincides with an important stock point – in control terms a main stock point – from which the customer has to be supplied.”. This section introduces the concept of decoupling, explores the pitfalls of tight coupling, and sets the stage for understanding how strategically implemented decoupling points can mitigate these challenges.

Decoupling Assignment Point “the point in the product axis to which the customer’s order penetrates. it is where order driven and the forecast driven activities meet. as a rule, the decoupling point coincides with an important stock point – in control terms a main stock point – from which the customer has to be supplied.”. This section introduces the concept of decoupling, explores the pitfalls of tight coupling, and sets the stage for understanding how strategically implemented decoupling points can mitigate these challenges. Decoupled inventory is when inventory, or finished goods, are separated from incoming raw materials, which are used to make those products. in short, it’s a method of reducing risk by separating inventories. a manufacturer will set aside decoupled inventory to ensure purchase orders remain fulfilled on time even in the event of possible disruption. Because supply chains tend to be extended with multiple levels of inventory between the point of production and the final marketplace, they tend to be forecast driven rather than demand driven. the point at which real demand penetrates upstream in a supply chain may be termed the decoupling point. What is a decoupling point? this is the point in the supply chain or manufacturing process where it makes the most sense to group components or unfinished products in a particular stage of production. Decoupling points play a crucial role in managing inventory along the supply chain by optimizing the balance between inventory levels, lead times, and responsiveness to ensure smooth operations and customer satisfaction.

Decoupling Explained Decoupled inventory is when inventory, or finished goods, are separated from incoming raw materials, which are used to make those products. in short, it’s a method of reducing risk by separating inventories. a manufacturer will set aside decoupled inventory to ensure purchase orders remain fulfilled on time even in the event of possible disruption. Because supply chains tend to be extended with multiple levels of inventory between the point of production and the final marketplace, they tend to be forecast driven rather than demand driven. the point at which real demand penetrates upstream in a supply chain may be termed the decoupling point. What is a decoupling point? this is the point in the supply chain or manufacturing process where it makes the most sense to group components or unfinished products in a particular stage of production. Decoupling points play a crucial role in managing inventory along the supply chain by optimizing the balance between inventory levels, lead times, and responsiveness to ensure smooth operations and customer satisfaction.

Decoupling Point Inventory Supply Chain What is a decoupling point? this is the point in the supply chain or manufacturing process where it makes the most sense to group components or unfinished products in a particular stage of production. Decoupling points play a crucial role in managing inventory along the supply chain by optimizing the balance between inventory levels, lead times, and responsiveness to ensure smooth operations and customer satisfaction.

Decoupling Point Explained What It Is And How To Use It

Comments are closed.