Compression Spring End Types There Are Two Basic

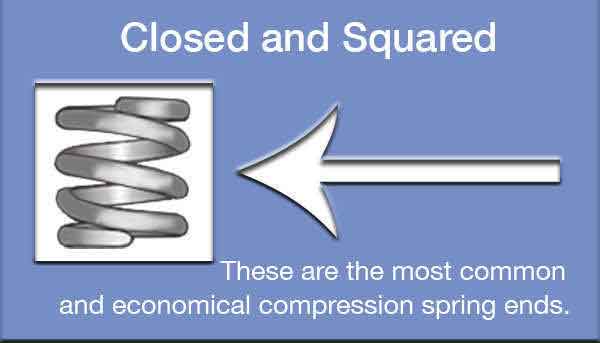

Compression Spring End Types Compression spring end types can be categorized into a few high level types. the first differentiator is whether or not the spring ends are open or closed ended. Closed and squared ends are the most popular type of ends in compression springs. these type of ends allows your spring to stand vertically when placed on a flat surface since the last coil on the ends is closed at the time it is being manufactured on the coiling cnc machine.

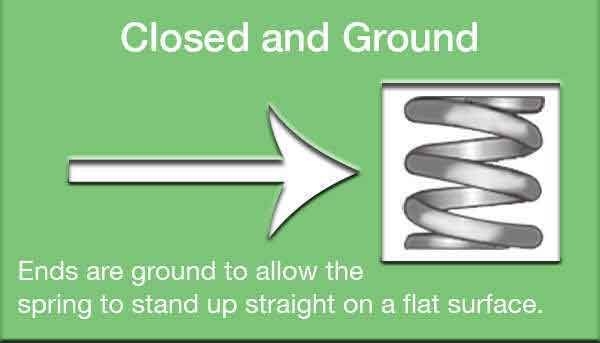

Compression Spring Supplier Compression Spring End Types Hd Png Springs with closed ends or with closed and ground ends have one inactive coil at each end. springs with open ends are considered to have virtually no inactive coil. These end types of compression springs, closed and ground, are more expensive but are also the most common. they are typically larger and designed for precision applications. If you are trying to buy a stock compression spring you might come across the dilemma of trying to select the end types you want your spring to have. the main types of ends for compression springs are: closed and squared, closed and ground, open ends, and double close and squared. Compression spring end types:there are two basic end types used for compression springs closed and open. each option offers the choice of either ground or no.

Compression Spring End Types Design Requirments Benefits If you are trying to buy a stock compression spring you might come across the dilemma of trying to select the end types you want your spring to have. the main types of ends for compression springs are: closed and squared, closed and ground, open ends, and double close and squared. Compression spring end types:there are two basic end types used for compression springs closed and open. each option offers the choice of either ground or no. Compression springs have different end types to accommodate various installation and functional requirements for different applications. the choice of end type will affect the interaction between the spring and the surrounding environment, as well as its performance in specific mechanisms. There are two basic types: helical (coil) torsion springs and spiral torsion springs. helical torsion springs are available in compression or extension springs and act in a radial direction when applying torque rather than axially to produce tension or compression. The compression spring design formulas to calculate its physical dimensions are provided below as well as how to choose a material type. there are several types of compression spring ends types. the most popular ends are closed and squared ends.

Compression Spring End Types Quality Spring Affordable Prices Compression springs have different end types to accommodate various installation and functional requirements for different applications. the choice of end type will affect the interaction between the spring and the surrounding environment, as well as its performance in specific mechanisms. There are two basic types: helical (coil) torsion springs and spiral torsion springs. helical torsion springs are available in compression or extension springs and act in a radial direction when applying torque rather than axially to produce tension or compression. The compression spring design formulas to calculate its physical dimensions are provided below as well as how to choose a material type. there are several types of compression spring ends types. the most popular ends are closed and squared ends.

Compression Spring End Types Quality Spring Affordable Prices The compression spring design formulas to calculate its physical dimensions are provided below as well as how to choose a material type. there are several types of compression spring ends types. the most popular ends are closed and squared ends.

Compression Spring End Types Quality Spring Affordable Prices

Comments are closed.