Commonly Used Industrial Robot Programming Methods Applications Of

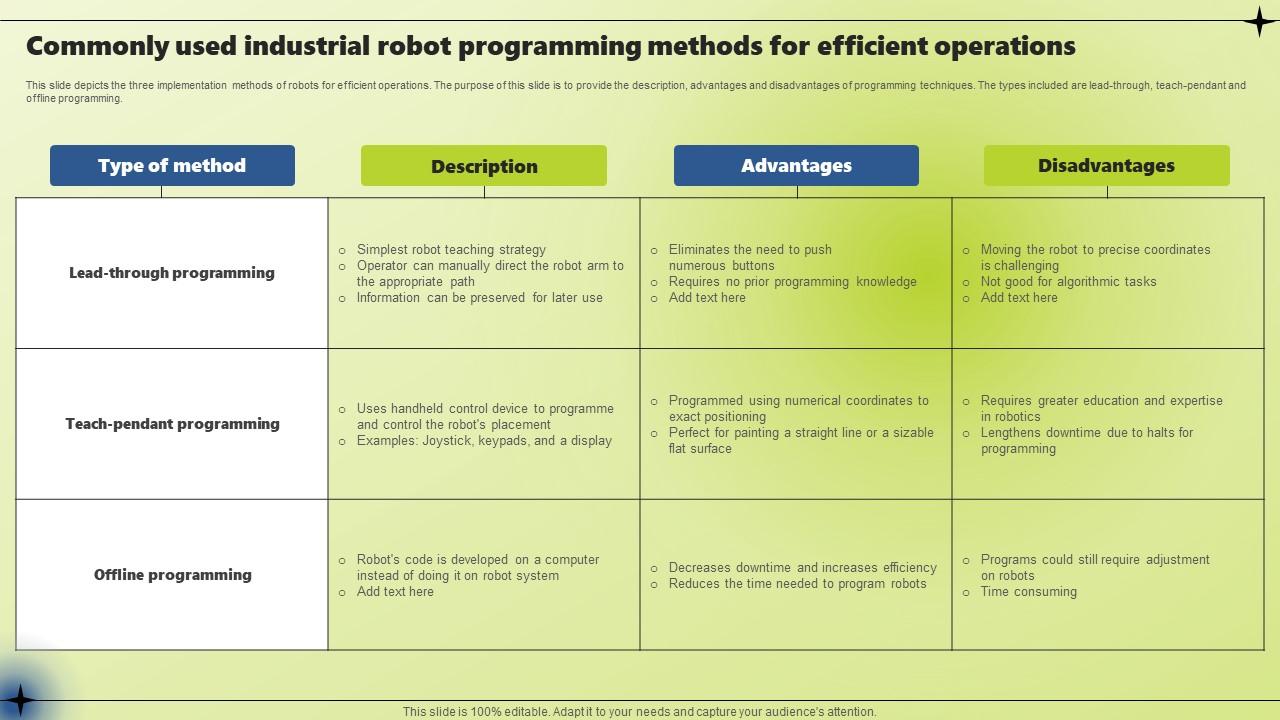

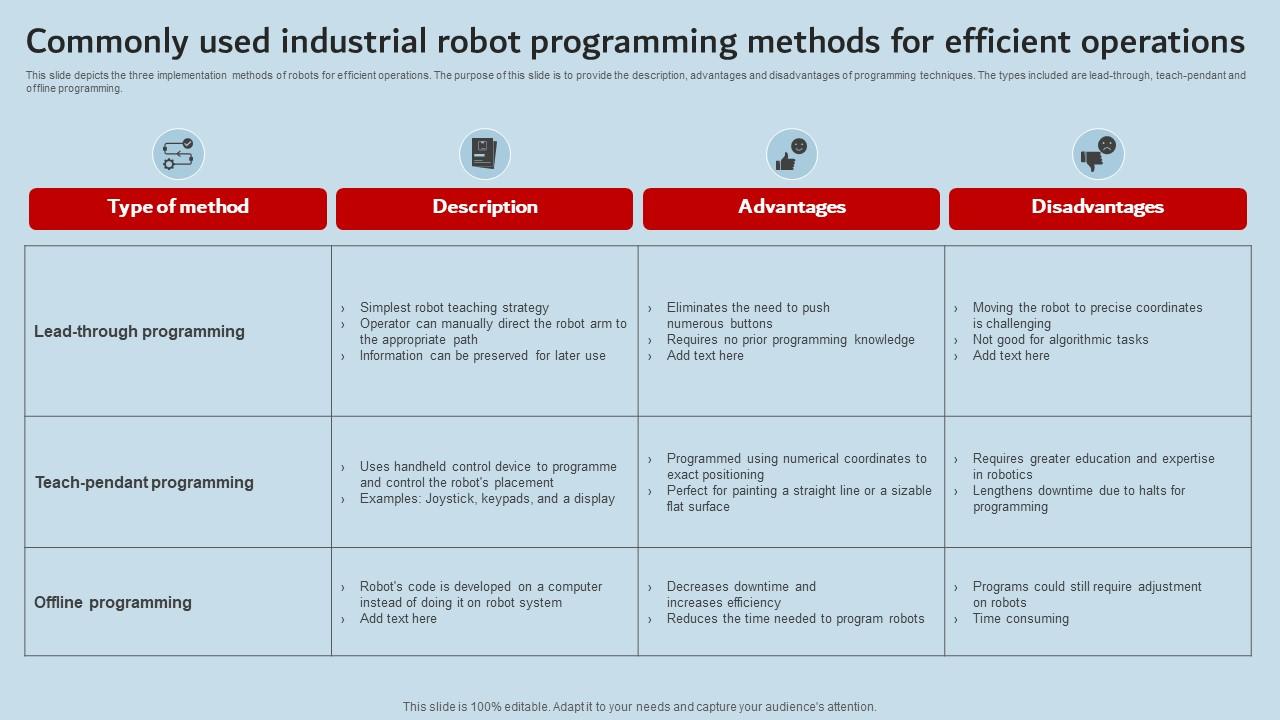

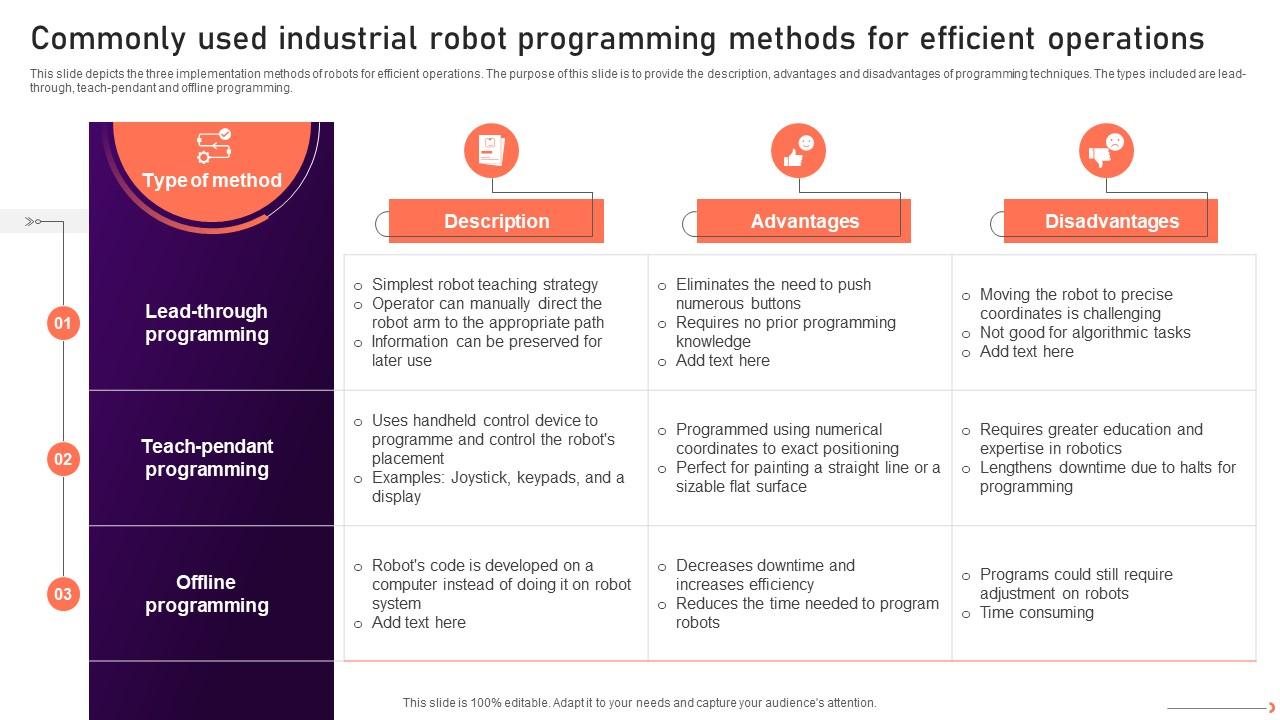

Commonly Used Industrial Robot Programming Methods Applications Of Robot programming is essential for automating tasks and enhancing productivity in various industries. there are 8 main types of robot programming, each with unique benefits and applications, including offline programming, online programming, and graphical programming. As robotics technology advances, new programming methods to simplify things for end users have emerged. there are three common teaching or programming methods. 1. lead through programming. lead through is the simplest of all robot teaching methods. with the servo controls turned off, the operator can manually move the robot arm to its desired path.

Commonly Used Industrial Robot Programming Methods Operations This paper provides a comprehensive review of the recent research progresses on the programming methods for industrial robots, including online programming, offline programming (olp), and programming using augmented reality (ar). Fortunately, advancements in robotics has led to the development of more intuitive programming methods that are user friendly to even the most novice of operators. today the most common programming methods for industrial robots are teach pendants, offline simulation, and lead through demonstration. teach pendants. Industrial robots are designed using a variety of techniques. let’s discuss the most common methods out of them. 1. teach pendant programming. in this method, as discussed, the programmer manually guides the robot through its tasks. the recorded coordinates are used to generate the steps the robot will follow during operation. These issues have stimulated the development of new technologies that support more efficient methods for robot control and programming. the goal of this research is to identify and evaluate the main approaches proposed in scientific papers and by the robotics industry in the last decades.

Industrial Robots Commonly Used Industrial Robot Programming Methods Industrial robots are designed using a variety of techniques. let’s discuss the most common methods out of them. 1. teach pendant programming. in this method, as discussed, the programmer manually guides the robot through its tasks. the recorded coordinates are used to generate the steps the robot will follow during operation. These issues have stimulated the development of new technologies that support more efficient methods for robot control and programming. the goal of this research is to identify and evaluate the main approaches proposed in scientific papers and by the robotics industry in the last decades. Programming involves creating instructions for machines to execute automated tasks, often used in industrial robots. manual and offline programming methods exist, with offline offering more flexibility and efficiency. Programming an industrial robot is a critical step in ensuring that the robot is able to perform a specific task. there are a variety of programming methods, each with its own specific application scenarios and benefits. overview of industrial robot programming. Each by showing’ methods. chronologically, the leadthrough methods represent the first real robot programm. g methods used in industry. they had their beginnings in the early 1960s when robots were first being used. programming: textual methods robot programming with textual languages is accomplished somewha. Two commonly used programming languages in robotics are robot programming language (rpl) and robotic operating system (ros). these languages provide a robust set of commands and functions specifically designed for controlling robots. rpl, a high level programming language, offers a user friendly interface for programming robots.

Commonly Used Industrial Robot Programming Methods For Efficient Programming involves creating instructions for machines to execute automated tasks, often used in industrial robots. manual and offline programming methods exist, with offline offering more flexibility and efficiency. Programming an industrial robot is a critical step in ensuring that the robot is able to perform a specific task. there are a variety of programming methods, each with its own specific application scenarios and benefits. overview of industrial robot programming. Each by showing’ methods. chronologically, the leadthrough methods represent the first real robot programm. g methods used in industry. they had their beginnings in the early 1960s when robots were first being used. programming: textual methods robot programming with textual languages is accomplished somewha. Two commonly used programming languages in robotics are robot programming language (rpl) and robotic operating system (ros). these languages provide a robust set of commands and functions specifically designed for controlling robots. rpl, a high level programming language, offers a user friendly interface for programming robots.

Top Industrial Applications In Robotic Applications Pdf Robot Each by showing’ methods. chronologically, the leadthrough methods represent the first real robot programm. g methods used in industry. they had their beginnings in the early 1960s when robots were first being used. programming: textual methods robot programming with textual languages is accomplished somewha. Two commonly used programming languages in robotics are robot programming language (rpl) and robotic operating system (ros). these languages provide a robust set of commands and functions specifically designed for controlling robots. rpl, a high level programming language, offers a user friendly interface for programming robots.

Comments are closed.