Common Mistakes In Root Cause Failure Analysis Part 7 How To Differentiate Rcfa From Fmea

Training Root Cause Failure Analysis Rcfa And Failure Modes And Don't forget to check out the rest of the series: part 1: • common rcfa mistakes part 1: writing part 2: • common rcfa mistakes part ii: the pro more. Root cause failure analysis (rcfa) is a structured, data driven process used to identify the underlying causes of problems or failures. the goal of rcfa is to determine the root cause of an issue, rather than just addressing the immediate or obvious symptoms.

3 Common Mistakes In Root Cause Failure Analysis Rcfa Paper 360 It is easy to make mistakes when performing a root cause failure analysis. keep reading to find out what some of the most common mistakes are and how to turn things around in your organization. Fmea is a flexible methodology for addressing potential failure points and implementing lasting changes. common mistakes are a normal occurrence in fmea but are easily addressed. proper implementation of this methodology should see minimal problems, with established documentation being present. These are common mistakes in root cause analysis and effective strategies to avoid them. enhance your rca efforts with practical tips for reliability experts. Machines aren’t supposed to break, and mechanical components such as shafts, fasteners, and structures aren’t supposed to fail. but when they do fail, they can tell us exactly why.

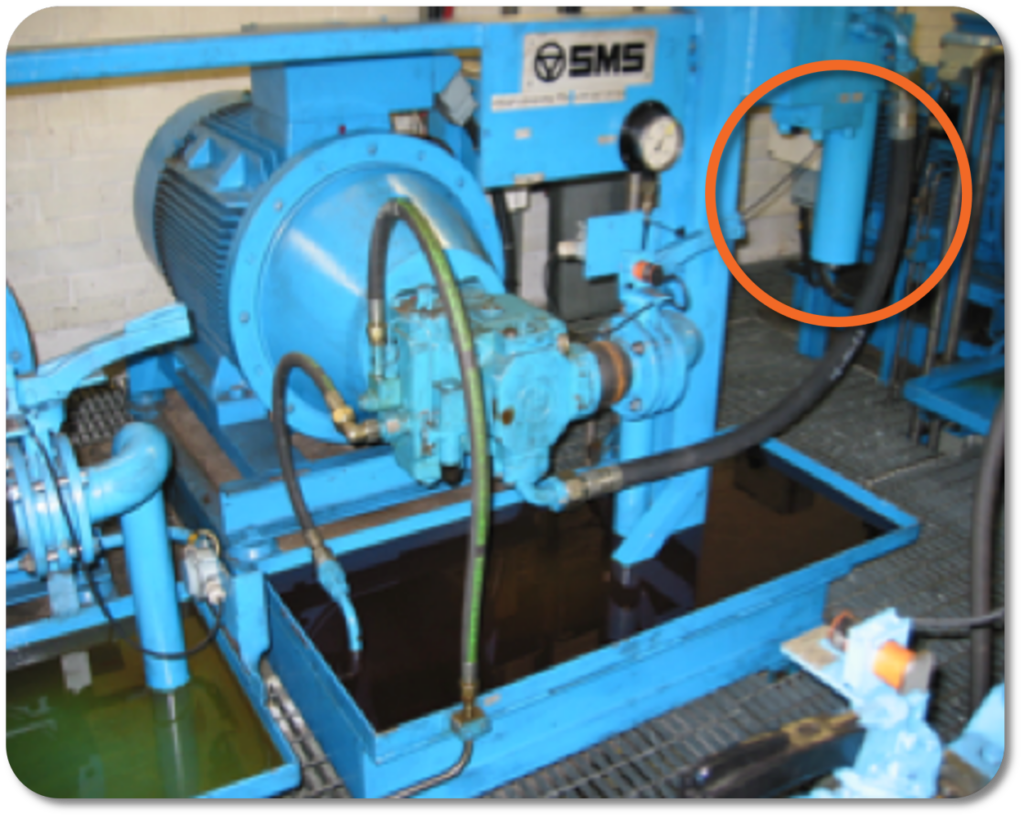

Rcfa Success Of Root Cause Failure Analysis Pdf These are common mistakes in root cause analysis and effective strategies to avoid them. enhance your rca efforts with practical tips for reliability experts. Machines aren’t supposed to break, and mechanical components such as shafts, fasteners, and structures aren’t supposed to fail. but when they do fail, they can tell us exactly why. Root cause and failure analysis (rcfa) is a structured process to identify the root cause of equipment failures. instead of just fixing the immediate issue, rcfa determines why the failure happened and implements corrective actions to prevent it from recurring. It is easy to make mistakes when performing a root cause failure analysis (rcfa)—we have all done it. this article will show you two common mistakes and how to overcome them. Have you been wondering why your rcfa process isn't working for you? tor will walk you through common mistakes typically made in the rcfa process and how to avoid them. Six such failures are examined in greater detail: repeat bearing failures that were attributed to vendor design error. extreme vibration and deterioration of grease lubricated sleeve bearings in large sea water intake pumps traceable to operations error.

Comments are closed.