Cleanroom Classification Design And

Cleanroom Classification Pdf Glasses Sodium Carbonate A cleanroom or clean room is an engineered space that maintains a very low concentration of airborne particulates. it is well isolated, well controlled from contamination, and actively cleansed. This is a simple and easy to understand guide on cleanrooms. learn what a cleanroom is, its classifications, components, and more.

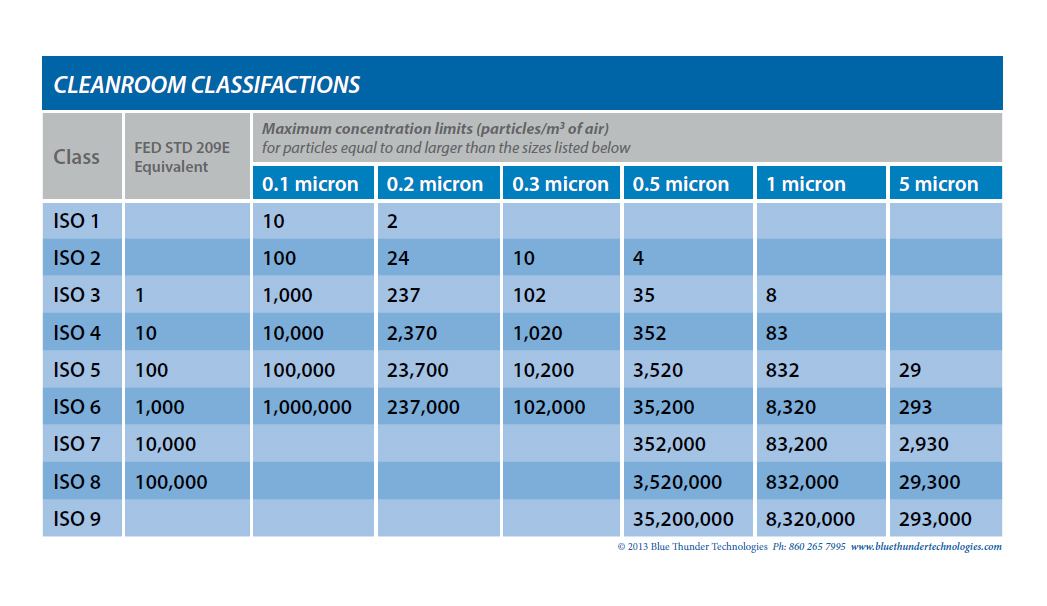

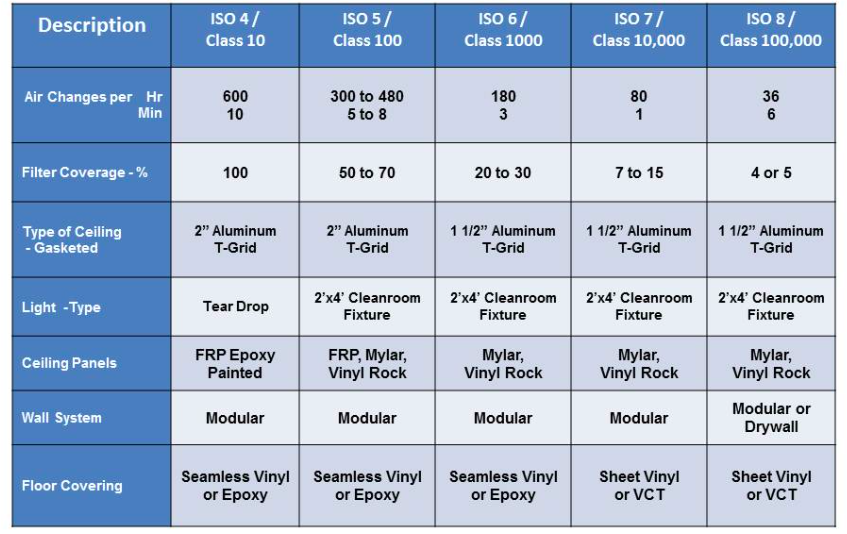

Cleanroom Classification Design Guidelines Lm Air 41 Off Cleanrooms are controlled environments designed to minimize airborne particles and contamination. ranging from iso class 1 (ultra clean) to iso class 9 (least stringent), these classifications guide industries in creating conditions tailored to their specific needs. Iso classifications measure the cleanroom level of cleanliness, according to the quantity and size of particles m3. learn more about iso standards. Cleanrooms are critical environments used across pharmaceutical manufacturing, biotechnology, aerospace, microelectronics, and medical device production. these spaces are engineered to control airborne contamination and ensure a consistently clean environment for sensitive processes. Cleanrooms are engineered to maintain ultra clean conditions by regulating airflow, filtration, humidity, temperature, pressure, and contamination sources.

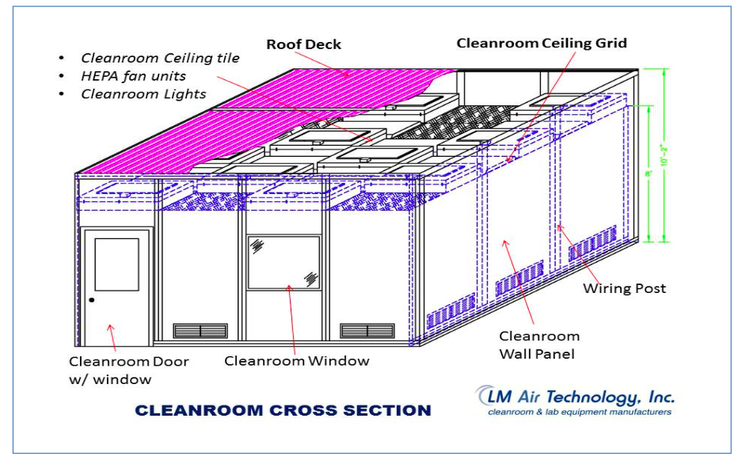

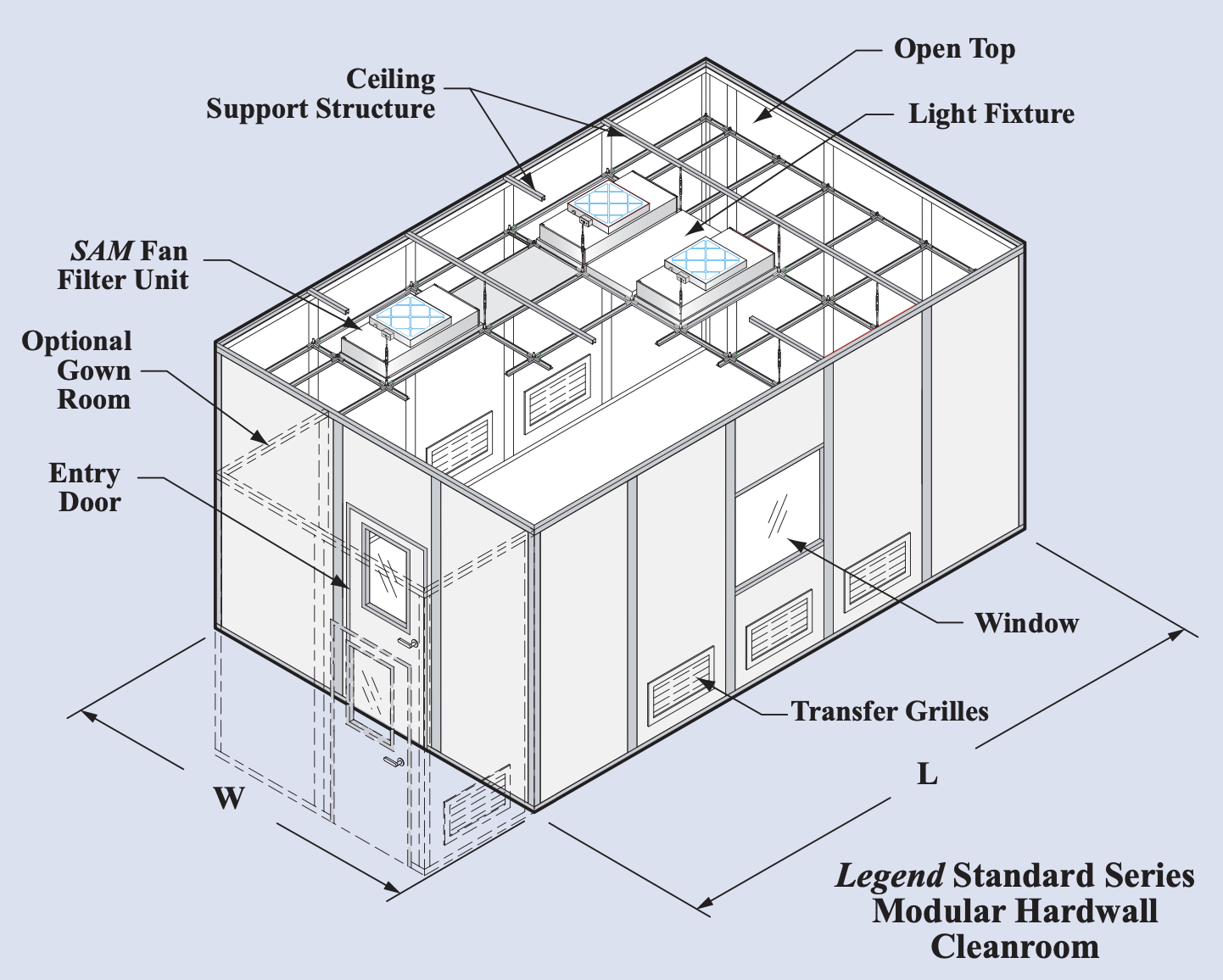

Cleanroom Classification Design Guidelines Lm Air 41 Off Cleanrooms are critical environments used across pharmaceutical manufacturing, biotechnology, aerospace, microelectronics, and medical device production. these spaces are engineered to control airborne contamination and ensure a consistently clean environment for sensitive processes. Cleanrooms are engineered to maintain ultra clean conditions by regulating airflow, filtration, humidity, temperature, pressure, and contamination sources. A cleanroom is an essential controlled environment in modern industries and scientific research, widely used in high precision fields such as semiconductor manufacturing, biopharmaceuticals, medical devices, and aerospace. this guide will provide a complete overview of cleanrooms, covering their definition, classification standards, key design elements, construction process, and future trends. Are you looking for the right cleanroom? learn the difference between the various iso classifications and standards and how they impact your workspace. What is a cleanroom? iso 14644 1: • 'a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimise the introduction, generation, and retention of particles & microbes inside the room and in which other relevant parameters, e.g. temperature, humidity, and pressure, are. What are cleanrooms? a cleanroom is a specially designed and controlled environment where the concentration of airborne particles is kept to a minimum. the primary purpose of a cleanroom is to prevent contamination of sensitive processes or products, ensuring their quality and safety.

Cleanroom Classification Design Guidelines Lm Air Technology A cleanroom is an essential controlled environment in modern industries and scientific research, widely used in high precision fields such as semiconductor manufacturing, biopharmaceuticals, medical devices, and aerospace. this guide will provide a complete overview of cleanrooms, covering their definition, classification standards, key design elements, construction process, and future trends. Are you looking for the right cleanroom? learn the difference between the various iso classifications and standards and how they impact your workspace. What is a cleanroom? iso 14644 1: • 'a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimise the introduction, generation, and retention of particles & microbes inside the room and in which other relevant parameters, e.g. temperature, humidity, and pressure, are. What are cleanrooms? a cleanroom is a specially designed and controlled environment where the concentration of airborne particles is kept to a minimum. the primary purpose of a cleanroom is to prevent contamination of sensitive processes or products, ensuring their quality and safety.

Cleanroom Classification Design Guidelines Lm Air Technology What is a cleanroom? iso 14644 1: • 'a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimise the introduction, generation, and retention of particles & microbes inside the room and in which other relevant parameters, e.g. temperature, humidity, and pressure, are. What are cleanrooms? a cleanroom is a specially designed and controlled environment where the concentration of airborne particles is kept to a minimum. the primary purpose of a cleanroom is to prevent contamination of sensitive processes or products, ensuring their quality and safety.

Cleanroom Classification Design Guidelines Lm Air 57 Off

Comments are closed.