Anvil Minus Elevation Wiki Fandom

Funballer Minus Elevation Wiki Fandom This is a list of manufacturers currently making anvils for blacksmiths and farriers: accaciao china, cast 1045 steel, hardness unknown atlas anvil usa, cast 1050 steel, 60 rc b&w china, cast 6150 steel, 58 60 rc [william] barnhart usa, cast 50mn steel, 57 rc big blu usa, cast steel. His anvil feet are distinctive. the divots punchmarks on the mark side opposite the weight are just where someone was playing or testing the temper of a ball punch.

Theater Minus Elevation Wiki Fandom However, a high rebound anvil does making smithing easier, but for a different reason. because more force is available to deform the workpiece when forging on a high rebound anvil, the smith is able to accomplish the same amount of metal movement with fewer hammer blows. Is it important (and if so, how and why) to have an anvil that's forged rather than cast? also, i'm interested in the distinction between cast iron and cast steel on anvils. iron and steel have so many strange and wild and "art more than science" properties, it seems . i looked around and altho. After doing alot of research, a week ago, i finally got my new holland 190lb anvil. i'm a newbie, but i have wanted to start blacksmithing for over a decade. my previous job included a lot of travel, and i was also probably foolishly) adamant about starting with a good anvil before i did anything. An anvil that is not connected to it's block will bounce, this also is stealing energy from your hammer blow. if you strike the anvil on the horn, or on the heel, you should notice much less rebound, and a "clonky" noise.

Anvil Minus Elevation Wiki Fandom After doing alot of research, a week ago, i finally got my new holland 190lb anvil. i'm a newbie, but i have wanted to start blacksmithing for over a decade. my previous job included a lot of travel, and i was also probably foolishly) adamant about starting with a good anvil before i did anything. An anvil that is not connected to it's block will bounce, this also is stealing energy from your hammer blow. if you strike the anvil on the horn, or on the heel, you should notice much less rebound, and a "clonky" noise. The anvil had a clip horn, a semi circular projection for drawing thin projections, called clips, from the edge of the horseshoe. the early patterns had one pritchel hole and the later patterns had two pritchel holes. the anvil heel was fairly thin compared to a blacksmiths' pattern anvil. Fisher anvils: made in newport, maine(1847 1852), then in trenton, nj at the original trenton plant(1853 1961), then finally by crossley machine works (1962 1979). currently owned by joshua kavett, howell tnsp, nj. made by a unique method of casting iron over the tool steel plates to implem. Put the anvil on a silicone base like alan sugested and that will isolate the anvil from its mount and dampen alot of the vertical resonance. a ring of putty around the waist will dampen the horizontal plane. I recently came across a hay budden blacksmithing anvil. i believe it's ~150 pounds. (there's a 1 space 52 stamped on the right side under the company name, etc.) can someone please post a (complete) range of hay budden serial numbers vs. manufacturing dates? i see several topics asking for the.

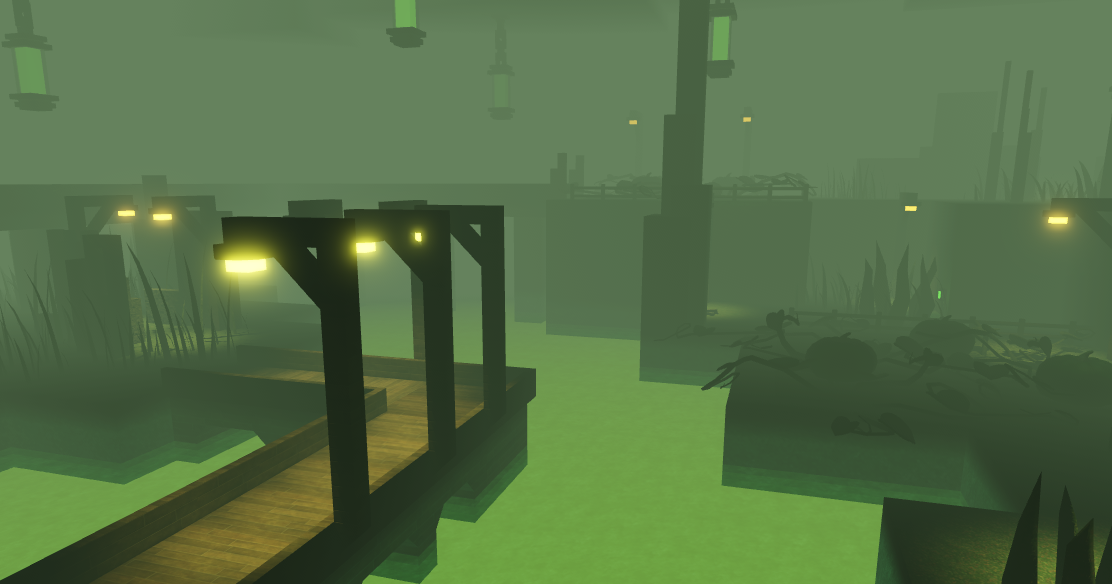

Swamplands Minus Elevation Wiki Fandom The anvil had a clip horn, a semi circular projection for drawing thin projections, called clips, from the edge of the horseshoe. the early patterns had one pritchel hole and the later patterns had two pritchel holes. the anvil heel was fairly thin compared to a blacksmiths' pattern anvil. Fisher anvils: made in newport, maine(1847 1852), then in trenton, nj at the original trenton plant(1853 1961), then finally by crossley machine works (1962 1979). currently owned by joshua kavett, howell tnsp, nj. made by a unique method of casting iron over the tool steel plates to implem. Put the anvil on a silicone base like alan sugested and that will isolate the anvil from its mount and dampen alot of the vertical resonance. a ring of putty around the waist will dampen the horizontal plane. I recently came across a hay budden blacksmithing anvil. i believe it's ~150 pounds. (there's a 1 space 52 stamped on the right side under the company name, etc.) can someone please post a (complete) range of hay budden serial numbers vs. manufacturing dates? i see several topics asking for the.

Comments are closed.