Analysing Big Data Csv Via Openai Api Api Openai Developer Forum

Analysing Big Data Csv Via Openai Api Api Openai Developer Community Implementing i p o into your current projects can be a fast and visual way of understanding workflow. while it can seem daunting to adopt a new methodology, you don’t need to worry. putting this methodology into action is quick and simple, as you’ll see throughout our guide. overview: what is input process output (i p o)? input process output (i p o) is a structured methodology for. How do verification and validation differ? find out how these concepts apply to your simulations in our comprehensive guide.

Analysing Big Data Csv Via Openai Api Api Openai Developer Community How do you deal with non normal data? normal data distributions are often misunderstood in six sigma, this guide covers effective strategies. How do you measure process work at your organization? you might want to incorporate a time study, as detailed in this in depth guide. What are standardized residuals? get the nitty gritty on how to calculate, interpret, and use standardized residuals from your data. Why should you ask why? the 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place.

Analysing Big Data Csv Via Openai Api Api Openai Developer Community What are standardized residuals? get the nitty gritty on how to calculate, interpret, and use standardized residuals from your data. Why should you ask why? the 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. Defects per unit, commonly known as dpu, is a measurement representing the average number of defects that occur with each product unit. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. this guide covers some handy tips. How do you implement the six sigma methodology? consider the 5w1h approach when implementing it for your organization. 5w1h (who, what, where, when, why, how) is a method of asking questions about a process or a problem taken up for improvement. four of the w’s (who, what, where, when) and the one h are used to comprehend details, analyze inferences and judgment to get to the fundamental. What is root cause and failure analysis? find out how rcfa can help you drill down to the underlying problems plaguing your production.

Analysing Big Data Csv Via Openai Api Api Openai Developer Community Defects per unit, commonly known as dpu, is a measurement representing the average number of defects that occur with each product unit. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. this guide covers some handy tips. How do you implement the six sigma methodology? consider the 5w1h approach when implementing it for your organization. 5w1h (who, what, where, when, why, how) is a method of asking questions about a process or a problem taken up for improvement. four of the w’s (who, what, where, when) and the one h are used to comprehend details, analyze inferences and judgment to get to the fundamental. What is root cause and failure analysis? find out how rcfa can help you drill down to the underlying problems plaguing your production.

Use Cli To Batch Download The Usage Data Of Openai Api Community How do you implement the six sigma methodology? consider the 5w1h approach when implementing it for your organization. 5w1h (who, what, where, when, why, how) is a method of asking questions about a process or a problem taken up for improvement. four of the w’s (who, what, where, when) and the one h are used to comprehend details, analyze inferences and judgment to get to the fundamental. What is root cause and failure analysis? find out how rcfa can help you drill down to the underlying problems plaguing your production.

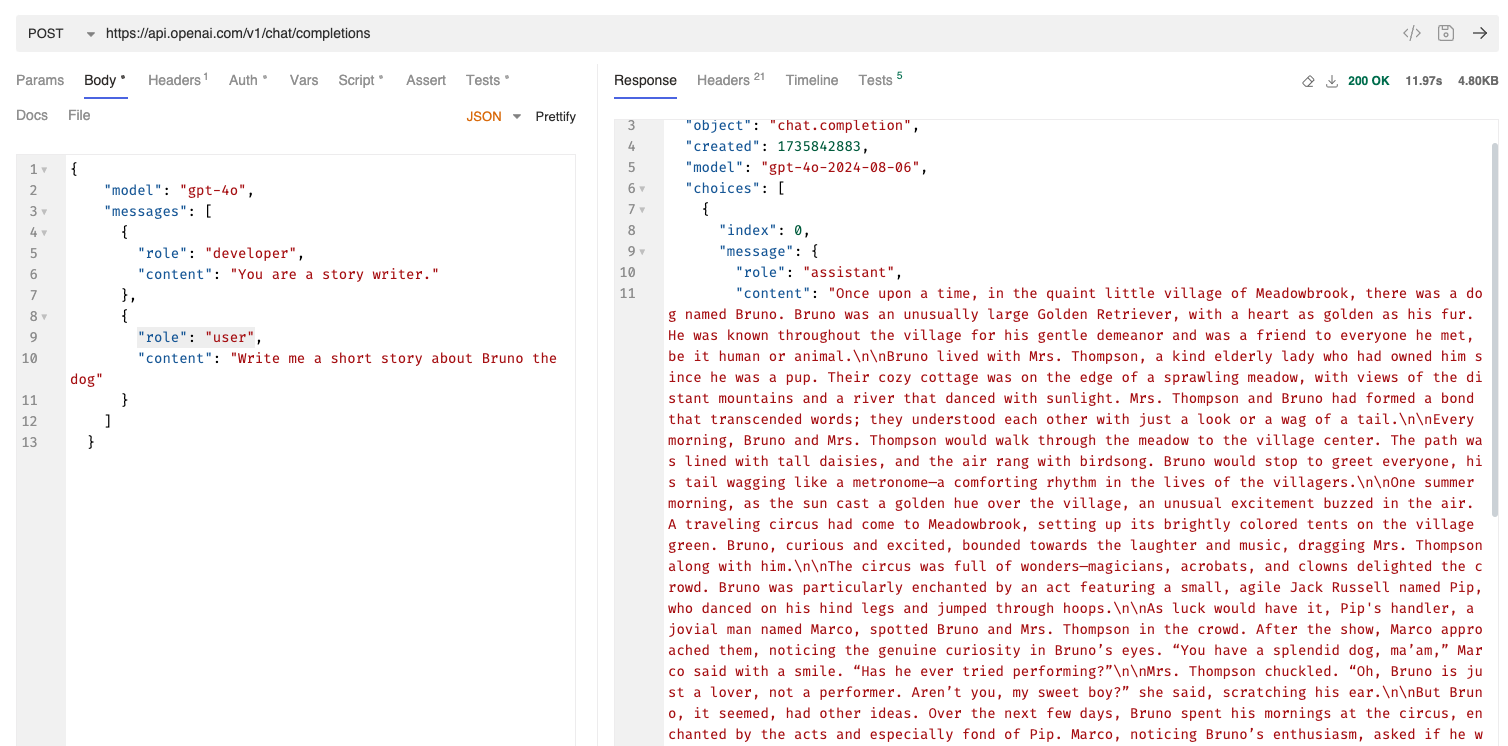

Story Time Via Openai Api

Comments are closed.